Chart Industries and Flowserve announce a merger of equals to create a differentiated leader in industrial process technologies. Learn More.

×

废弃物发电厂

废弃物发电在负责任地管理废弃物并生成可再生非化石燃料能源方面发挥着重要作用,Howden 的汽轮机、风机和换热器在整个过程中实现高效运行。

Howden 的产品已在从大型传统电站到使用城市垃圾和生物质作为燃料的小型电站等各类电力生产行业中得到验证。Howden 的每一件设备都旨在实现最高效的性能并提供可靠的运行保障。

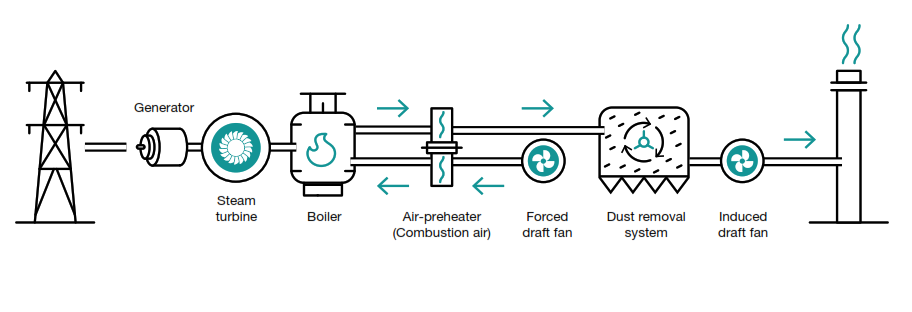

无论是以城市生活垃圾 (MSW) 还是以生物质作为燃料,垃圾发电厂都会通过燃烧过程产生蒸汽,为汽轮发电机提供动力。

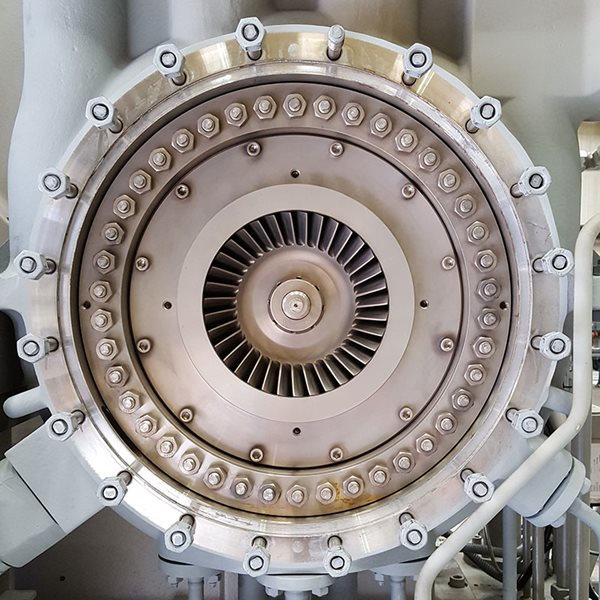

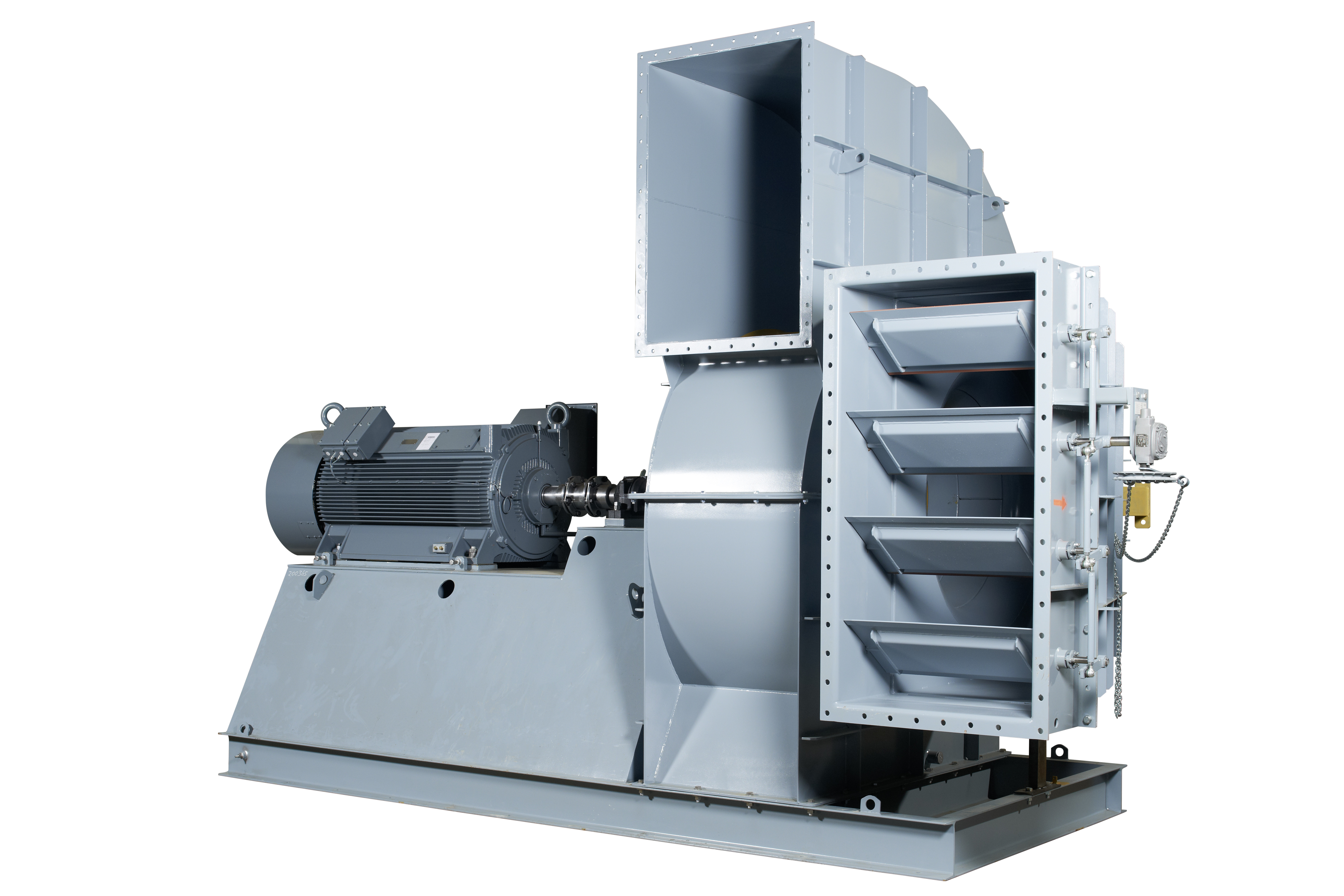

Howden 的设备在燃烧过程中发挥着重要作用。离心风机被作为强制通风(FD)风机部署,为废弃物燃烧过程提供新鲜空气;同时也作为引风(ID)风机使用,将烟气通过除尘系统抽出。

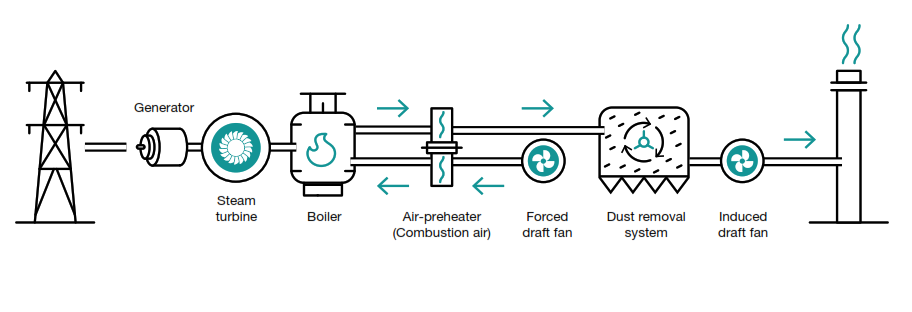

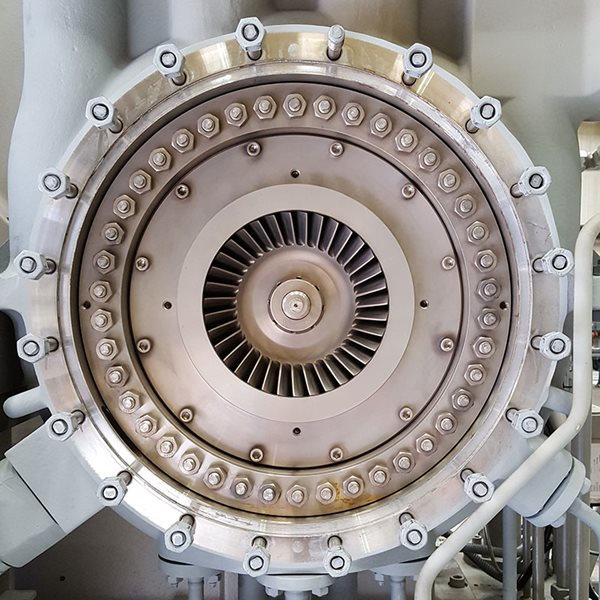

锅炉中产生的蒸汽可用于区域供热的工艺蒸汽,或驱动汽轮机发电。Howden 的传统汽轮机品牌(Kühnle, Kopp & Kausch 和 Peter Brotherhood)因其能够应对负载变化、在不同输出之间灵活切换而闻名。

通过对燃烧空气进行预热,可以提高燃烧效率。为此,Howden 提供再生回转式空气预热器,该设备以大约 1-2 rpm 的速度缓慢旋转,利用薄金属换热元件从热烟气中吸收热量,并将其传递给进入系统的冷空气。

典型应用场景无论是以城市生活垃圾 (MSW) 还是以生物质作为燃料,垃圾发电厂都会通过燃烧过程产生蒸汽,为汽轮发电机提供动力。

Howden 的设备在燃烧过程中发挥着重要作用。我们的离心风机被部署为强制通风(FD)风机,为废弃物燃烧提供新鲜空气;也被用作引风(ID)风机,将烟气抽出并通过除尘系统。

锅炉中产生的蒸汽可用于区域供热的工艺蒸汽,或驱动汽轮机发电。Howden 的汽轮机品牌(Kühnle、Kopp & Kausch 和 Peter Brotherhood)因其可灵活应对负载变化而著称,能实现不同能量输出间的切换。

通过对燃烧空气进行预热,可以提高燃烧效率。为此,Howden 提供再生回转式空气预热器,该设备以大约 1-2 rpm 的速度缓慢旋转,利用薄金属换热元件从热烟气中吸收热量,并将其传递给进入系统的冷空气。

典型应用场景Howden 以 Kühnle、Kopp & Kausch 和 Peter Brotherhood 的传统为基础,能够满足从标准可配置的蒸汽透平机到完全定制的解决方案的需求。我们的汽轮机在全球垃圾发电厂中已实现超过 1000 MW 的装机容量。它们被广泛应用于小型工业发电、余热回收及可再生能源系统中。

项目示例垃圾形式多样,我们的汽轮机可利用由城市垃圾焚烧、工业过程废蒸汽或木质生物质产生的蒸汽驱动。我们的一位客户(锯木厂)使用我们的汽轮机发电 24MW;另一位客户通过焚烧污泥回收 3.3MW 能源。

我们的汽轮机还被用于支持农业废弃物能源转换,比如西班牙一位客户使用橄榄废料驱动一台 8MW 的汽轮机。该汽轮机为工厂提供蒸汽,同时将电力输送至电网。另一客户通过焚烧肉骨粉(MBM)产生 14MW 的电能,供应给当地工业与家庭。

制糖行业也是使用废料发电的重要领域。“甘蔗渣”(甘蔗废料)被燃烧以产生蒸汽,满足工艺需求和电力输出。我们已为该细分市场供应了超过 500 台汽轮机。

我们生产从配置简单到完全工程化的风机,可满足各种客户需求。我们拥有知识、经验和能力,可以针对特定需求调整和开发新设计,这在我们的工程能力中可见一斑。

所有风机均旨在最大限度地提高运行效率,根据应用和工况不同,部分风机的效率可达 90% 以上。

再生空气预热器旨在提高锅炉效率,增幅可达 10-15%。

封装空气预热器产品系列为希望回收燃烧设备能量的用户提供一种高效、低维护、占地紧凑的解决方案。它可以处理每小时不到 50 吨到每小时大约 200 吨的烟气流,并且根据气体温度下降,回收的能量可以扩展到 15MW 以上。

这些换热器适用于集成到新工厂开发中,以及运营场所内的替代技术更换。所有换热器都有豪顿全球售前和售后服务的全面支持,可确保项目工程的简易性和长期获得可靠的性能。

Howden 拥有多种风机产品,满足不同性能需求,在冷却效率与噪音水平方面均表现出色,无论冷却系统如何设计。

我们的风机可应用于冷却塔、空冷冷凝器与空气冷却热交换器,具备高达 250 Pa 的低压降与高达 3000 m³/s 的高风量能力。

荷兰 Twence 垃圾发电厂在炎热夏季需要提升汽轮机的性能与输出。这可通过提高汽轮机背压、进而提升水-蒸汽循环效率来实现。前提是必须保持现有噪音排放水平以符合当地法规。

他们需要增加空冷冷凝器(ACC)中的气流量。虽然提高现有风机转速可达成这一目标,但速度增加也会导致噪音上升。因此他们选择了 Howden 的 SXT 超低噪音风机,它在较低转速下提供更高风量。SXT 风机还能适配现有风机环,显著节省安装时间与资本支出。

安装了 10 台 SXT 风机,使每个风机的气流量增加了约 29%。风机安装后,在相同的环境温度和蒸汽流量下,工厂功率输出增加了约 10.5%

该工厂进一步部署了 Howden Uptime(我们的状态监测系统),以减少冷却风机的非计划维护,提升效率和生产力。

Howden 的售后服务始终致力于降低成本与停机时间,同时提升运行性能。与我们合作是实现设备在生命周期内持续高效运行、最小停机的关键。

维护及维修针对废弃物发电厂,我们提供涵盖整个流程的全面售后解决方案,包括轴流风机、离心风机、冷却风机、压缩机、换热器、电除尘器、汽轮机、齿轮箱和发电机等。

Howden 的维护理念是通过在可用性与可靠性之间找到最优平衡,来最小化设备总拥有成本。我们通过彻底调查故障并防止其再次发生来保障可靠性。凭借我们的工程经验与用户反馈,我们不断优化维护策略与计划,形成一套全面灵活的模块化系统,旨在主动优化您的工厂运行绩效。

备件Howden 提供正品 OEM 备件,这些备件按照与我们的产品相同的高性能标准制造。这意味着每个部件都将完美契合,并维持您的工艺设备可靠高效运行所需的高质量标准。

蒸汽涡轮发电机服务借助我们的子公司 Maintenance Partners 的能力,我们可为各类品牌的汽轮机、齿轮箱和发电机提供服务、备件及升级服务。

Howden Uptime 是一款独特的数字化解决方案,能采集任何旋转设备的物理传感器数据,并分析其运行状态与环境响应。

该方案旨在提供关键的设备性能洞察,从而提升设备可用性并显著降低成本。Howden Uptime 带来以下好处:

Howden 以 Kühnle、Kopp & Kausch 和 Peter Brotherhood 的传统为基础,能够满足从标准可配置的蒸汽透平机到完全定制的解决方案的需求。我们的汽轮机在全球垃圾发电厂已交付超过 1000MW 的装机容量。它们被广泛应用于小型工业发电、余热回收及可再生能源系统中。

项目示例垃圾形式多样,我们的汽轮机可利用由城市垃圾焚烧、工业过程废蒸汽或木质生物质产生的蒸汽驱动。我们的一位客户(锯木厂)使用我们的汽轮机发电 24MW;另一位客户通过焚烧污泥回收 3.3MW 能源。

我们的汽轮机被用于农业废弃物发电,比如西班牙一客户使用橄榄废料驱动一台 8MW 的汽轮机。该汽轮机为工厂提供蒸汽,同时将电力输送至电网。另一客户焚烧肉骨粉(MBM)产生 14MW 的电能,供应给当地工业和家庭。

制糖行业也是使用废料发电的重要领域。“甘蔗渣”(甘蔗废料)被燃烧以产生蒸汽,满足工艺需求和电力输出。我们已为该细分市场供应了超过 500 台汽轮机。

我们生产从配置简单到完全工程化的风机,可满足各种客户需求。我们拥有知识、经验和能力,可以针对特定需求调整和开发新设计,这在我们的工程能力中可见一斑。

所有风机均旨在最大限度地提高运行效率,根据应用和工况不同,部分风机的效率可达 90% 以上。

再生空气预热器旨在提高锅炉效率,增幅可达 10-15%。

封装空气预热器产品系列为希望回收燃烧设备能量的用户提供一种高效、低维护、占地紧凑的解决方案。它可以处理每小时不到 50 吨到每小时大约 200 吨的烟气流,并且根据气体温度下降,回收的能量可以扩展到 15MW 以上。

这些换热器适用于集成到新工厂开发中,以及运营场所内的替代技术更换。所有换热器都有豪顿全球售前和售后服务的全面支持,可确保项目工程的简易性和长期获得可靠的性能。

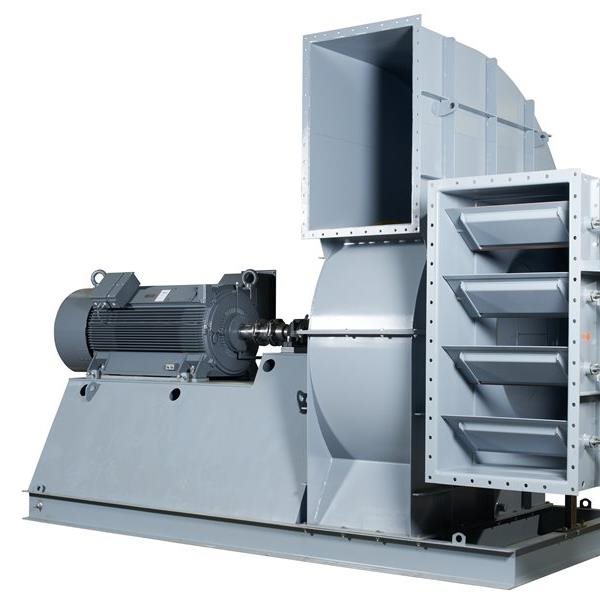

Howden 拥有多种风机产品,满足不同性能需求,在冷却效率与噪音水平方面均表现出色,无论冷却系统如何设计。

我们的风机可应用于冷却塔、空冷冷凝器与空气冷却热交换器,具备高达 250 Pa 的低压降与高达 3000 m³/s 的高风量能力。

参考项目荷兰 Twence 垃圾发电厂在炎热夏季需要提升汽轮机的性能与输出。这可通过提高汽轮机背压、进而提升水-蒸汽循环效率来实现。前提是必须保持现有噪音排放水平以符合当地法规。

他们需要增加空冷冷凝器(ACC)中的气流量。虽然提高现有风机转速可达成这一目标,但速度增加也会导致噪音上升。因此他们选择了 Howden 的 SXT 超低噪音风机,它在较低转速下提供更高风量。SXT 风机还能适配现有风机环,显著节省安装时间与资本支出。

安装了 10 台 SXT 风机,使每个风机的气流量增加了约 29%。风机安装后,在相同的环境温度和蒸汽流量下,工厂功率输出增加了约 10.5%

该工厂进一步部署了 Howden Uptime(我们的状态监测系统),以减少冷却风机的非计划维护,提升效率和生产力。

Howden 的售后服务始终致力于降低成本与停机时间,同时提升运行性能。与我们合作是实现设备在生命周期内持续高效运行、最小停机的关键。

维护及维修针对废弃物发电厂,我们提供涵盖整个流程的全面售后解决方案,包括轴流风机、离心风机、冷却风机、压缩机、换热器、电除尘器、汽轮机、齿轮箱和发电机等。

Howden 的维护理念是通过在可用性与可靠性之间找到最优平衡,来最小化设备总拥有成本。我们通过彻底调查故障并防止其再次发生来保障可靠性。凭借我们的工程经验与用户反馈,我们不断优化维护策略与计划,形成一套全面灵活的模块化系统,旨在主动优化您的工厂运行绩效。

备件Howden 提供正品 OEM 备件,这些备件按照与我们的产品相同的高性能标准制造。这意味着每个部件都将完美契合,并维持您的工艺设备可靠高效运行所需的高质量标准。

蒸汽涡轮发电机服务借助我们的子公司 Maintenance Partners 的能力,我们可为各类品牌的汽轮机、齿轮箱和发电机提供服务、备件及升级服务。

Howden Uptime 是一款独特的数字化解决方案,能采集任何旋转设备的物理传感器数据,并分析其运行状态与环境响应。

该方案旨在提供关键的设备性能洞察,从而提升设备可用性并显著降低成本。Howden Uptime 带来以下好处:

电话:+44 141 885 7500