Chart Industries and Flowserve announce a merger of equals to create a differentiated leader in industrial process technologies. Learn More.

×

离心压缩机

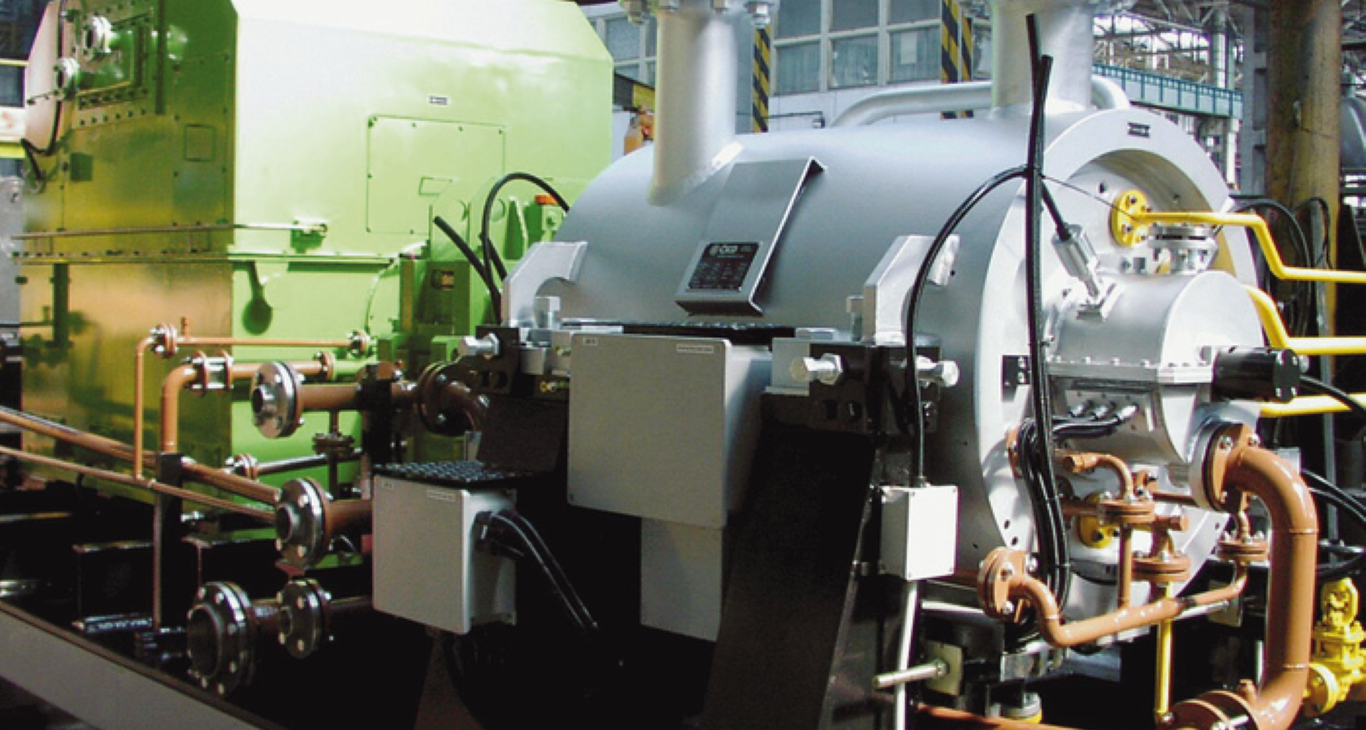

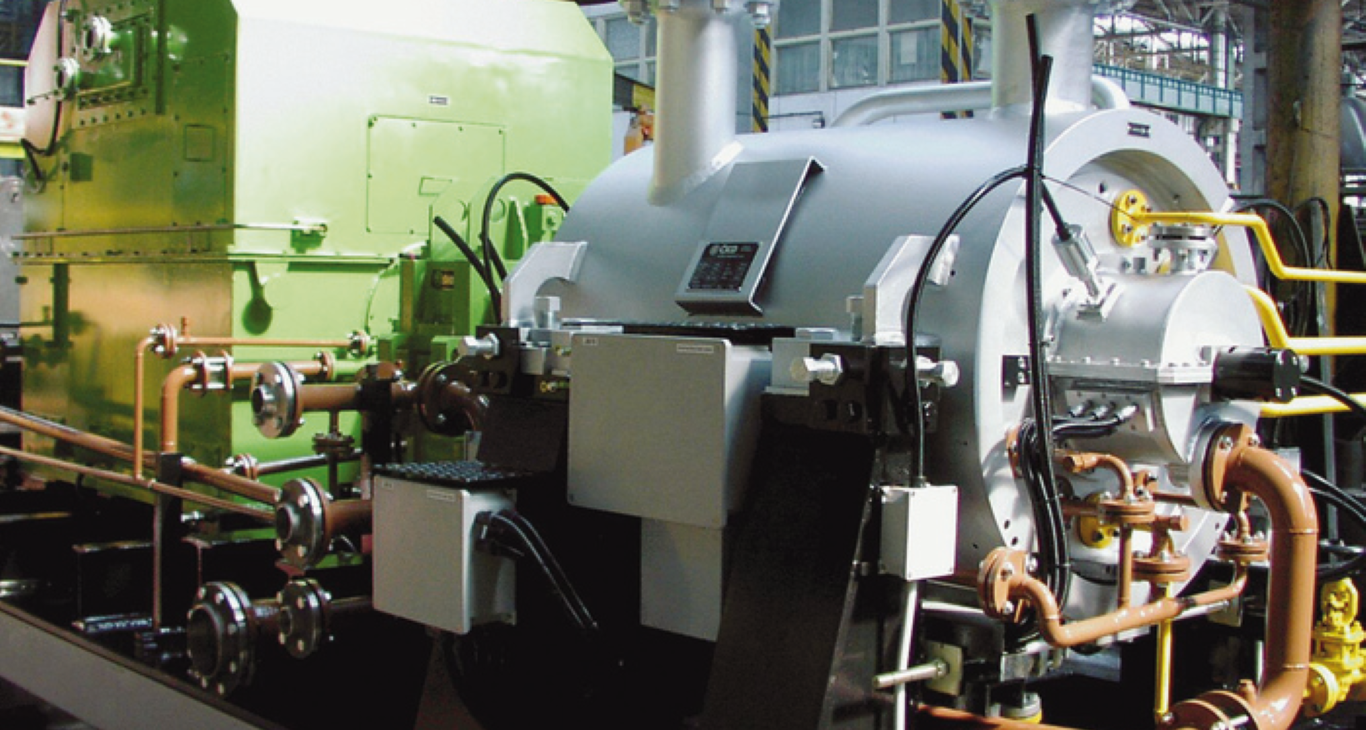

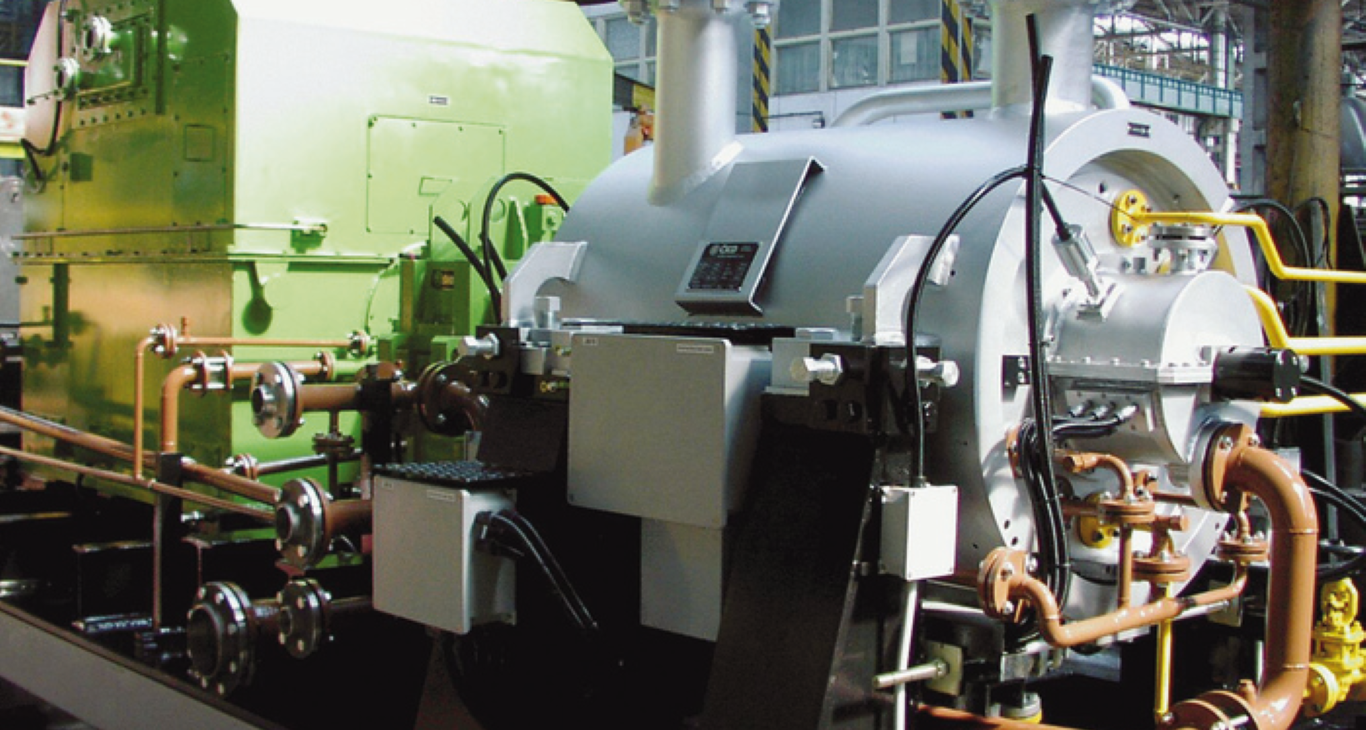

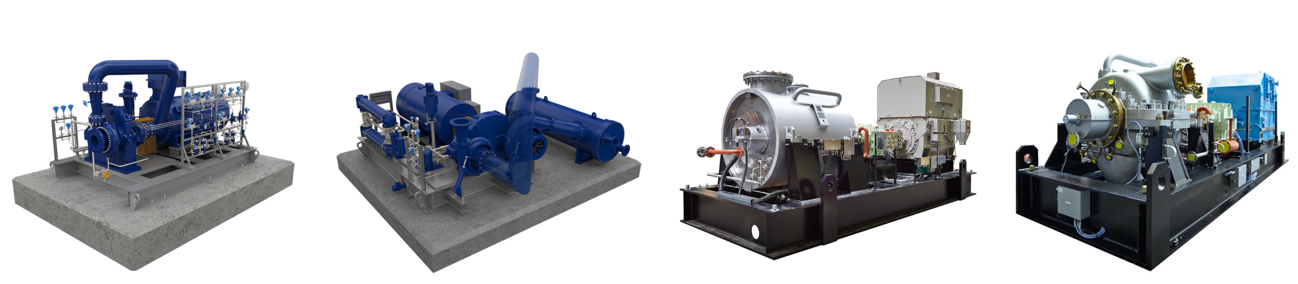

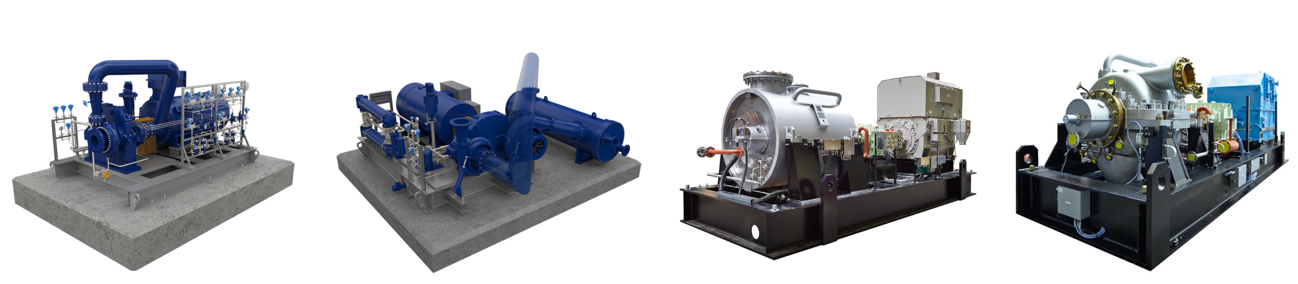

工业透平压缩机可满足冶金、石油和天然气以及化工行业的需求。

豪顿提供全系列的工业离心式透平压缩机,流量高达 600,000 m3/h,可灵活满足您的特定应用要求。我们的标准化装置采用模块化设计,可确保生命周期内的投资成本低,且交付时间短。我们的解决方案最常应用于冶金、化工和石化工厂。

多种化工生产过程需要对气体进行输送与压缩。一些气体通常具有腐蚀性、侵蚀性和粘性,因此需要高度工程化的压缩机以确保在严苛环境中可靠运行。

Howden 的 KK&K 和 CKD 品牌压缩机在安全性和可靠性方面树立了行业标准,同时具备最低生命周期成本。

典型应用场景

硫是使用最广泛的化学品之一,是化工和制造业中许多工艺的关键中间体。

硫酸厂 (SAP) 用于肥料和己内酰胺/发烟硫酸生产、冶金冶炼烟气净化(脱硫过程)、酸浸(如镍生产)、以及在石化或炼油过程中的酸回收。

Howden 的 KK&K 硫酸风机在硫酸生产中发挥着关键作用。它们专为应对不平衡、腐蚀和侵蚀的高要求而设计,树立了效率、可靠性和坚固性的标准。适用产品

碳化煤形式的焦炭是重要的能源,主要用于金属提取过程中的还原剂。在炼焦过程中会产生大量粗焦炉煤气。这些粗煤气需通过冷却、过滤和提取有价值产品进行净化以形成清洁燃气。

Howden 自 1902 年起通过 Kühnle、Kopp & Kausch 品牌制造焦炭气体风机。作为技术领导者,Howden 在焦炭气体风机方面设定了效率、可靠性和坚固性的标准,能应对含有毒性、有粘性成分的恶劣操作环境。

相关产品

许多工业过程涉及蒸发、结晶或蒸馏,

这些过程通常在热和蒸汽生成方面消耗大量能源。我们的压缩机可通过机械蒸汽再压缩提高这些过程的效率,即回收热能并将其再用于过程,从而降低能源需求。

Howden 在该应用方面拥有深厚的专业知识,产品组合丰富,包括能满足工程要求的离心压缩机。

通常,我们的压缩机能够在单级实现目标温升,凭借其坚固设计和先进材料,能承受苛刻工况。

典型过程包括:

制冷或工艺冷却是某些石化生产过程中关键的一部分。

冷却过程通常涉及大量气体与多级压缩。

典型工艺应用场景

直接还原铁 (DRI) 工艺因其能在多种类型的炉中生产出高质量的铁和钢产品而闻名。由于该工艺使用气体而非焦炭,当与氢气作为燃料气体结合用于生产绿色钢铁时,也被视为金属行业脱碳的一种有前景的方法。

Howden 的单级和多级一体化齿轮压缩机被广泛应用于各类 DRI 工艺中,以实现钢铁制造过程中 CO2 的减排。

多种化工生产过程需要对气体进行输送与压缩。一些气体通常具有腐蚀性、侵蚀性和粘性,因此需要高度工程化的压缩机以确保在严苛环境中可靠运行。

Howden 的 KK&K 和 CKD 品牌压缩机在安全性和可靠性方面树立了行业标准,同时具备最低生命周期成本。

典型应用场景

硫是使用最广泛的化学品之一,是化工和制造业中许多工艺的关键中间体。

硫酸厂 (SAP) 用于肥料和己内酰胺/发烟硫酸生产、冶金冶炼烟气净化(脱硫过程)、酸浸(如镍生产)、以及在石化或炼油过程中的酸回收。

Howden 的 KK&K 硫酸风机在硫酸生产中发挥着关键作用。它们专为应对不平衡、腐蚀和侵蚀的高要求而设计,树立了效率、可靠性和坚固性的标准。适用产品

碳化煤形式的焦炭是重要的能源,主要用于金属提取过程中的还原剂。在炼焦过程中会产生大量粗焦炉煤气。这些粗煤气需通过冷却、过滤和提取有价值产品进行净化以形成清洁燃气。

Howden 自 1902 年起通过 Kühnle、Kopp & Kausch 品牌制造焦炭气体风机。作为技术领导者,Howden 在焦炭气体风机方面设定了效率、可靠性和坚固性的标准,能应对含有毒性、有粘性成分的恶劣操作环境。

相关产品

许多工业过程涉及蒸发、结晶或蒸馏,

这些过程通常在热和蒸汽生成方面消耗大量能源。我们的压缩机可通过机械蒸汽再压缩提高这些过程的效率,即回收热能并将其再用于过程,从而降低能源需求。

Howden 在该应用方面拥有深厚的专业知识,产品组合丰富,包括能满足工程要求的离心压缩机。

通常,我们的压缩机能够在单级实现目标温升,凭借其坚固设计和先进材料,能承受苛刻工况。

典型过程包括:

制冷或工艺冷却是某些石化生产过程中关键的一部分。

冷却过程通常涉及大量气体与多级压缩。

典型工艺应用场景

直接还原铁 (DRI) 工艺因其能在多种类型的炉中生产出高质量的铁和钢产品而闻名。由于该工艺使用气体而非焦炭,当与氢气作为燃料气体结合用于生产绿色钢铁时,也被视为金属行业脱碳的一种有前景的方法。

Howden 的单级和多级一体化齿轮压缩机被广泛应用于各类 DRI 工艺中,以实现钢铁制造过程中 CO2 的减排。

相关产品

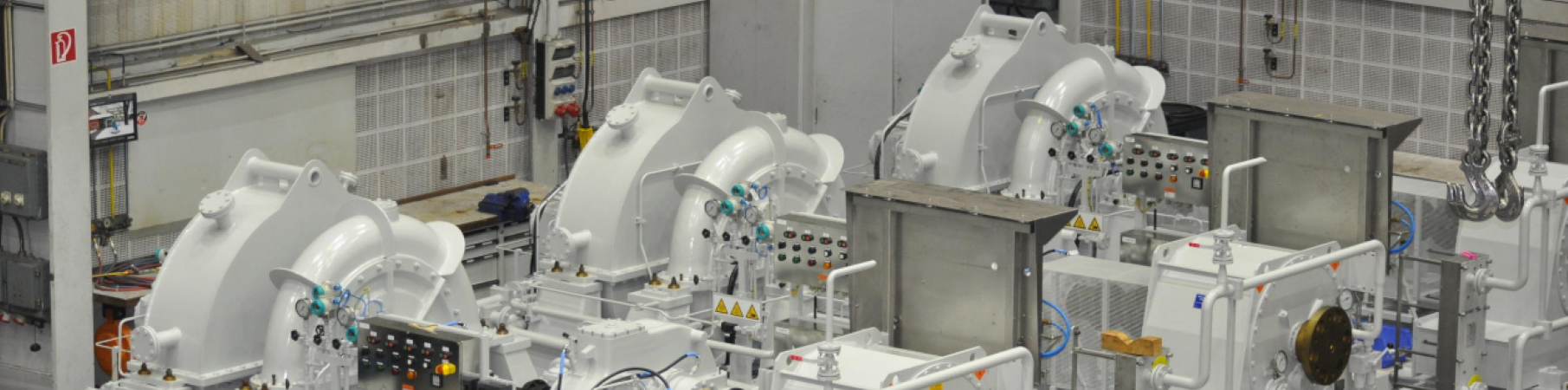

Kühnle, Kopp & Kausch (KK&K) 压缩机公司成立于 1899 年,并于 2017 年加入 Howden,为化工和金属等工业生产中的气体应用提供服务。

压缩机可采用单级设计和多级设计,可满足高达 600,000 m3/h 的高流量要求,单级压缩机高达 3.5 的升压,多级压缩机高达 6 的升压。

Českomoravská-Kolben-Daněk (CKD) 压缩机公司成立于 1927 年,并于 2013 年加入 Howden,为石油和天然气、石化、电力和钢铁行业的气体应用提供服务。

压缩机采用多级设计,可满足高达 1700,000 m3/h 的流量要求和高达 20 MPa 的排放压力。

Howden 的单级离心压缩机来自 Kühnle、Kopp 和 Kausch 品牌。型号范围适用于需要 3,000 m3/h 和 600,000 m3/h 流量且压力比高达 3.5 的应用。

型号范围的摘要视图:

| 型号 | 流量(m3/h) | 压力比 | 叶轮直径(毫米) | 驱动器 | 应用 |

|---|---|---|---|---|---|

| SF | 15,000-600,000 | 高达 3.5 | 高达 2240 | 电气或涡轮 | 适用于工业、化工以及油气行业中的各类气体处理工艺。用于工业蒸发工艺和 SAGD(重油开采的蒸汽辅助重力泄油)中的机械蒸汽再压缩工艺 |

| SFG | 5,000-300,000 | 高达 3.5 | 高达 1120 | 电气或涡轮 | 适用于工业、化工以及油气行业中的各类气体处理工艺。用于工业蒸发工艺和 SAGD 中的机械蒸汽再压缩。用于工业和金属行业的空气服务 |

| ST | 1,500-150,000 | 高达 3.5 | 高达 900 | 蒸汽涡轮机(集成) | 化学品生产中的空气和气体处理过程。废酸再生SAGD 内的机械蒸汽再压缩 |

| SL | 15,000-450,000 | 高达 1.45 | 高达 1800 | 电气或涡轮 | 焦炉气 |

Howden 的多级离心压缩机来自 Kühnle、Kopp 和 Kausch 以及 Českomoravská-Kolben-Daněk (CKD) 品牌。型号范围适用于需要 400 m3/h 和 200,000 m3/h 流量且压力比高达 10.0 的应用。

型号范围的摘要视图:

| 型号 | 流量(m3/h) | 压力比 | 叶轮直径(毫米) | 驱动器 | 应用 |

|---|---|---|---|---|---|

| SFG 背靠背 | 3,000-75,000 | 高达 6.0 | 高达 560 | 电气或涡轮 | 多种化学和石化应用。 |

| SFG 双结构 | 3,000-200,000 | 高达 6.0 | 高达 900 | 电气或涡轮 | 工业蒸发工艺,包含零液体排放。蒸汽辅助重力泄油。工艺空气转炉空气。直接还原铁 (DRI) 和高炉气体中的气体工艺。碳捕获和储存 |

| RS | 400-65,000 | 高达 10.0 | 高达 700 | 电气或涡轮 | 石化生产和化学/化肥内的工艺气体。石化装置制冷。焦炉气 |

| RV | 400-85,000 400-170,000(双列和双机组) |

高达 10.0 | 高达 780 | 电气或涡轮 | 石化生产和化学/化肥内的工艺气体。石化装置制冷。焦炉气 |

Howden 的单级离心压缩机来自 Kühnle、Kopp 和 Kausch 品牌。型号范围适用于需要 3,000 m3/h 和 600,000 m3/h 流量且压力比高达 3.5 的应用。

型号范围的摘要视图:

| 型号 | 流量(m3/h) | 压力比 | 叶轮直径(毫米) | 驱动器 | 应用 |

|---|---|---|---|---|---|

| SF | 15,000-600,000 | 高达 3.5 | 高达 2240 | 电气或涡轮 | 适用于工业、化工以及油气行业中的各类气体处理工艺。用于工业蒸发工艺和 SAGD(重油开采的蒸汽辅助重力泄油)中的机械蒸汽再压缩工艺 |

| SFG | 5,000-300,000 | 高达 3.5 | 高达 1120 | 电气或涡轮 | 适用于工业、化工以及油气行业中的各类气体处理工艺。用于工业蒸发工艺和 SAGD 中的机械蒸汽再压缩。用于工业和金属行业的空气服务 |

| ST | 1,500-150,000 | 高达 3.5 | 高达 900 | 蒸汽涡轮机(集成) | 化学品生产中的空气和气体处理过程。废酸再生SAGD 内的机械蒸汽再压缩 |

| SL | 15,000-450,000 | 高达 1.45 | 高达 1800 | 电气或涡轮 | 焦炉气 |

Howden 的多级离心压缩机来自 Kühnle、Kopp 和 Kausch 以及 Českomoravská-Kolben-Daněk (CKD) 品牌。型号范围适用于需要 400 m3/h 和 200,000 m3/h 流量且压力比高达 10.0 的应用。

型号范围的摘要视图:

| 型号 | 流量(m3/h) | 压力比 | 叶轮直径(毫米) | 驱动器 | 应用 |

|---|---|---|---|---|---|

| SFG 背靠背 | 3,000-75,000 | 高达 6.0 | 高达 560 | 电气或涡轮 | 多种化学和石化应用。 |

| SFG 双结构 | 3,000-200,000 | 高达 6.0 | 高达 900 | 电气或涡轮 | 工业蒸发工艺,包含零液体排放。蒸汽辅助重力泄油。工艺空气转炉空气。直接还原铁 (DRI) 和高炉气体中的气体工艺。碳捕获和储存 |

| RS | 400-65,000 | 高达 10.0 | 高达 700 | 电气或涡轮 | 石化生产和化学/化肥内的工艺气体。石化装置制冷。焦炉气 |

| RV | 400-85,000 400-170,000(双列和双机组) |

高达 10.0 | 高达 780 | 电气或涡轮 | 石化生产和化学/化肥内的工艺气体。石化装置制冷。焦炉气 |

查看并下载销售资料、技术手册等。

总部 +49 6233 85 2532