Chart Industries and Flowserve announce a merger of equals to create a differentiated leader in industrial process technologies. Learn More.

×

回转式热交换器

Howden 的烟气换热器和空气预热器可回收原本会浪费的热量,在多种工业流程中发挥提高能源效率的关键作用。

自上世纪初相关技术出现以来,Howden 一直走在提高以锅炉为核心的发电厂以及燃制换热器行业的效率的前沿。早在 20 世纪 30 年代,Howden 的换热器便开始应用于烟气脱硫 (FGD) 系统,随后也应用于选择性催化还原 (SCR) 系统,以优化排放控制效果。

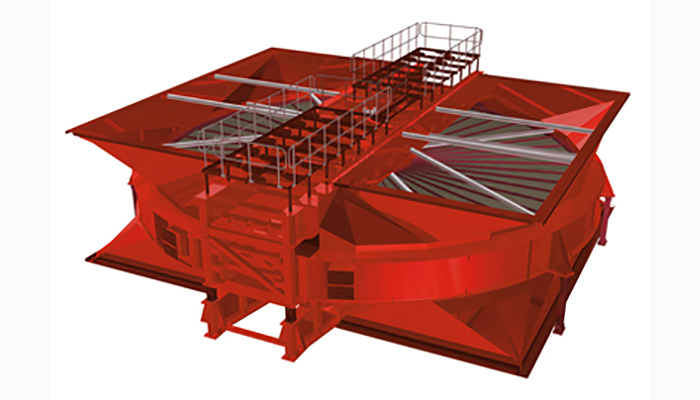

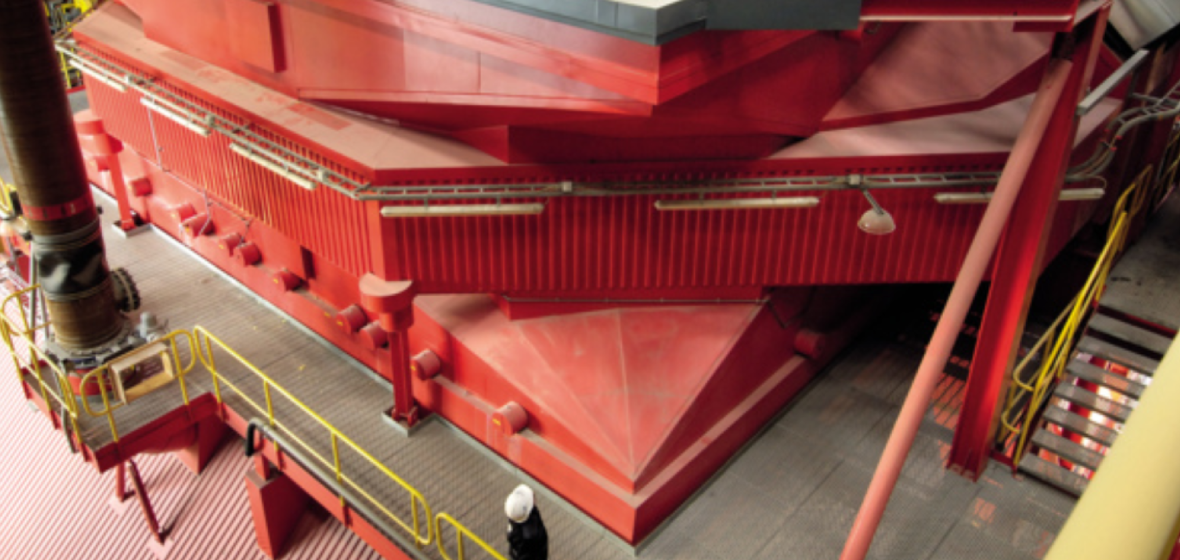

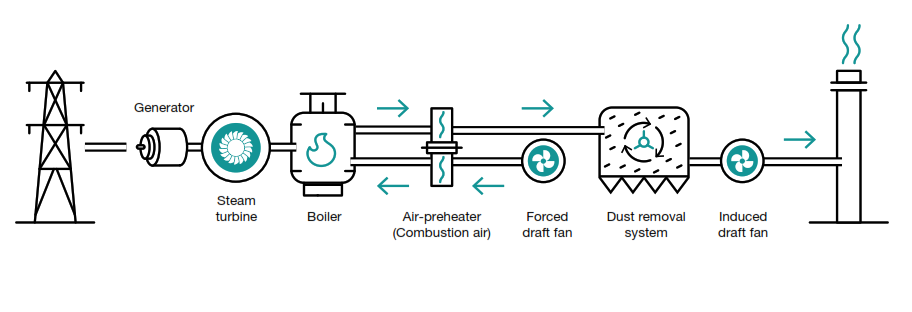

再生空气预热器在废气离开炉膛时从废气中提取废热,并将此能量传递给炉膛中使用的入口空气,以提供氧气来燃烧燃料。

预热器以约 1-2 rpm 的速度缓慢旋转,薄金属传热元件从热气流中吸收热量并将其传递到进入的冷空气流中。

目标: 将锅炉、熔炉或燃制换热器的效率提高 10%-15%。

典型应用场景

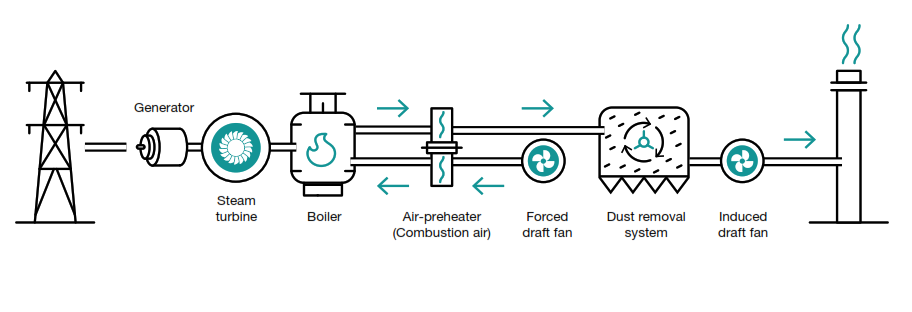

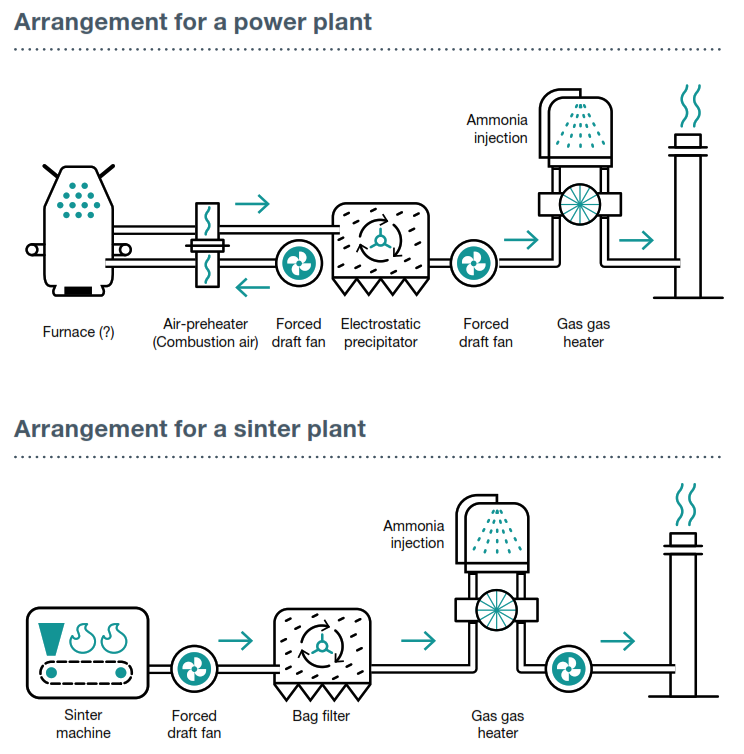

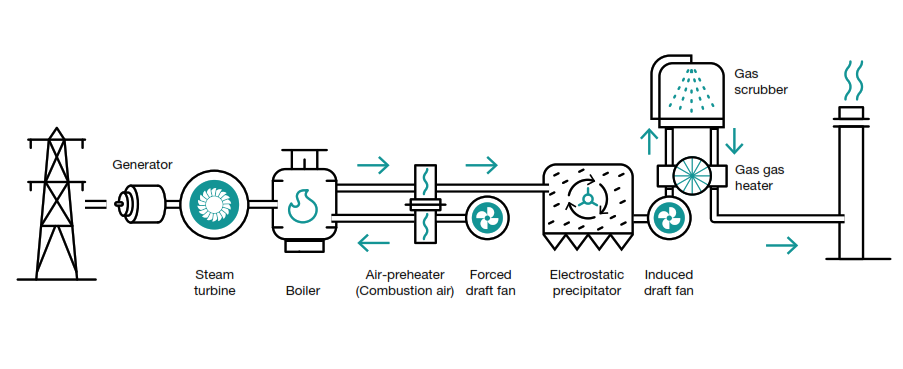

二氧化硫是一种有害的酸性气体,是化石燃料燃烧过程的副产物。随着 FGD 技术被引入以清除废气,回转式换热器又找到了新的应用方向。

许多 FGD 系统都设计有气体再热器(GGH),以降低吸收塔前的烟气温度,并对处理过的气体进行再热,从而产生“干”烟囱。这确保了足够的羽流浮力,并防止地面 SO2 浓度超过法规限值。

GGH 减少吸收塔中的用水量,并消除烟囱液体排放。它还避免了酸腐蚀和排水堵塞导致的高烟囱翻新成本以及维护问题。

再生气体/气体换热器通过吸收薄金属传热元件中的废热,从进入 FGD 洗涤器的未处理气体中回收能量。元件通常以约 0.5-1 rpm 旋转,以将热量传递到被发送到烟囱的经处理气体。

目标: 通过将处理过的气体重新加热到所需的浮力水平,辅助 SOX 处理过程并降低成本。

典型应用场景

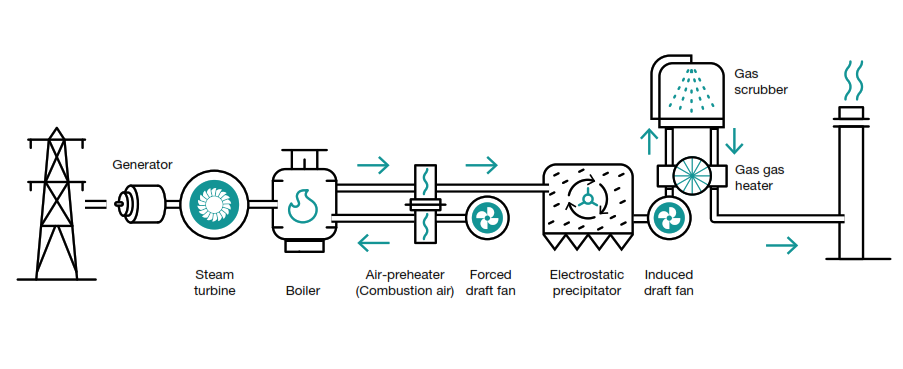

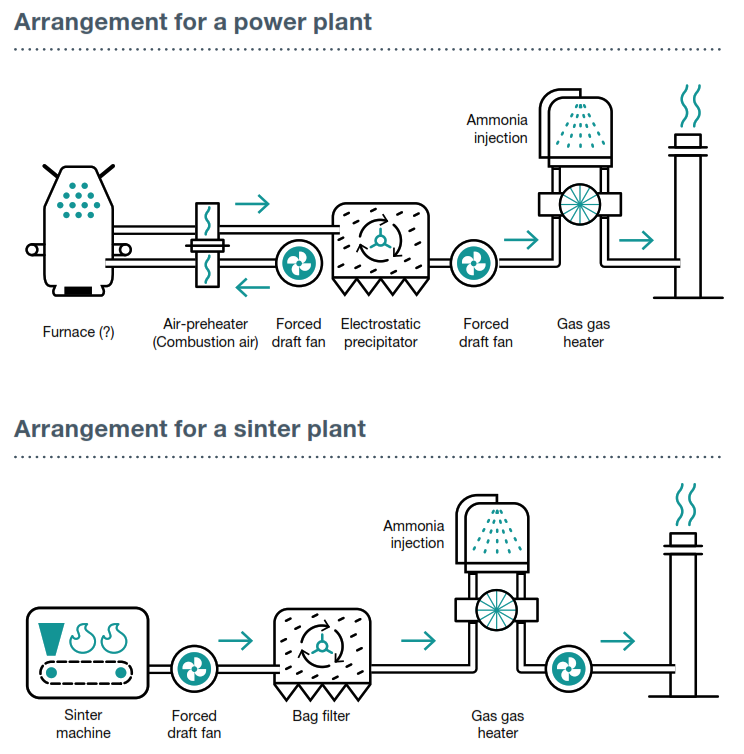

一氧化氮是化石燃料燃烧过程中排放的一种有害气体。随着选择性催化还原 (SCR) 技术被引入用于控制排放,回转式换热器获得了新的重要应用。

部分工厂因 SCR 无法安装在省煤器处,采用“尾端低尘 SCR”布局减少 NOx 排放。

再生气体/气体换热器 (GGH) 通过吸收薄金属传热元件中的废热,从离开 SCR 的处理过的气体中回收能量。在此应用中,加热元件以 0.6-1 rpm 的速度旋转,将热量传递给未处理的气体进料,从而降低达到反应温度所需的额外加热水平。

目标: 通过减少达到 NOX (≈ 250 - 330oC) 破坏反应温度所需的额外加热来提高 NOX 排放系统的效率。

典型应用场景

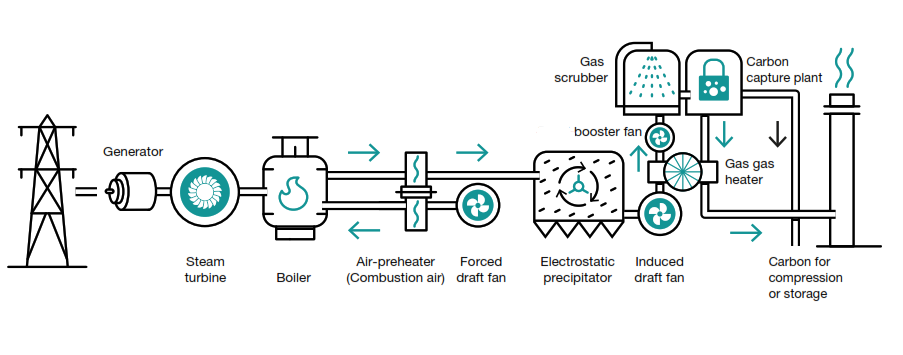

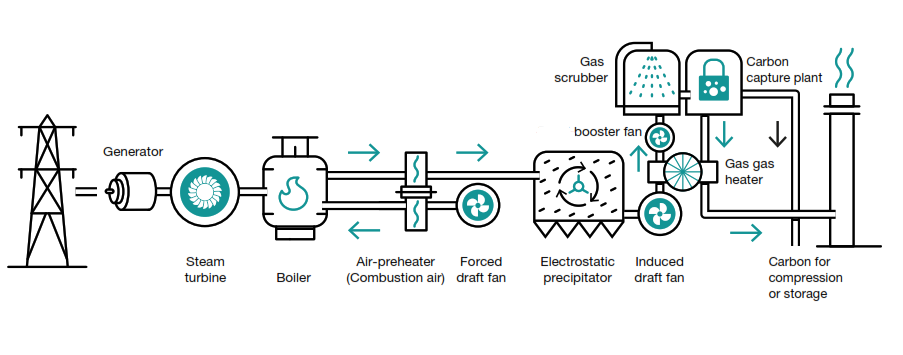

随着工业向碳捕获与封存 (CCS) 迈进,回转式换热器技术也被整合进新方案中。

燃烧后碳捕获 (PCC) 工厂可以作为新发电厂的一部分进行开发或改造。它们捕获烟气中的二氧化碳 (CO2),用作产品或储存在永久性地下地质储存设施中。

该工艺的换热器类似于烟气换热器 (GGH),其温度与 FGD 工艺相似。该换热器的作用是在烟气脱硫装置之前冷却烟气,并在碳捕获装置之后重新加热处理过的气体,以便排放到烟囱。

目标: 降低捕获装置前未处理气体的温度,并利用该温度重新加热处理过的气体,以降低羽流可见度并具有足够的浮力以离开烟囱。

适用产品

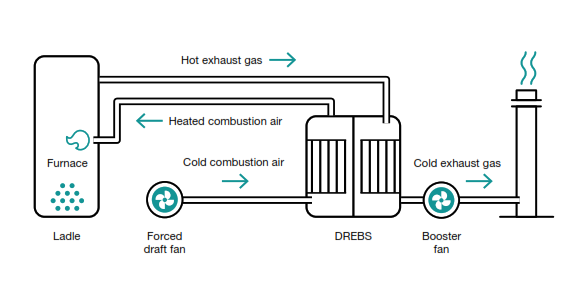

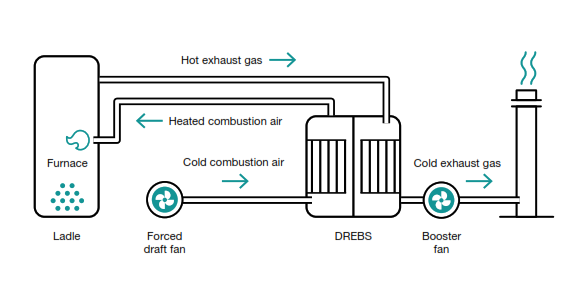

众多工业过程需高温加热,能耗极大。这些过程消耗大量能源,因此任何减少需求的方法都可以节省大量运营成本。

Howden Rothemühle 品牌推出的 DREBS 换热器为此提供了解决方案。这是一种旋转再生器燃烧器系统,利用陶瓷表面从高温废气中吸热,再通过旋转将热量传递给空气流。

与传统热回收器相比,DREBS 可应用于更高温度(高达 1200oC)。由于热效率高达 >85%,与传统换热器相比,节能效果可翻倍。

目标: 与传统换热器相比,燃烧器和干燥器的效率可提高高达 100%。

典型应用

再生空气预热器在废气离开炉膛时从废气中提取废热,并将此能量传递给炉膛中使用的入口空气,以提供氧气来燃烧燃料。

预热器以约 1-2 rpm 的速度缓慢旋转,薄金属传热元件从热气流中吸收热量并将其传递到进入的冷空气流中。

目标: 将锅炉、熔炉或燃制换热器的效率提高 10%-15%。

典型应用场景

二氧化硫是一种有害的酸性气体,是化石燃料燃烧过程的副产物。随着 FGD 技术被引入以清除废气,回转式换热器又找到了新的应用方向。

许多 FGD 系统都设计有气体再热器(GGH),以降低吸收塔前的烟气温度,并对处理过的气体进行再热,从而产生“干”烟囱。这确保了足够的羽流浮力,并防止地面 SO2 浓度超过法规限值。

GGH 减少吸收塔中的用水量,并消除烟囱液体排放。它还避免了酸腐蚀和排水堵塞导致的高烟囱翻新成本以及维护问题。

再生气体/气体换热器通过吸收薄金属传热元件中的废热,从进入 FGD 洗涤器的未处理气体中回收能量。元件通常以约 0.5-1 rpm 旋转,以将热量传递到被发送到烟囱的经处理气体。

目标: 通过将处理过的气体重新加热到所需的浮力水平,辅助 SOX 处理过程并降低成本。

典型应用场景

一氧化氮是化石燃料燃烧过程中排放的一种有害气体。随着选择性催化还原 (SCR) 技术被引入用于控制排放,回转式换热器获得了新的重要应用。

部分工厂因 SCR 无法安装在省煤器处,采用“尾端低尘 SCR”布局减少 NOx 排放。

再生气体/气体换热器 (GGH) 通过吸收薄金属传热元件中的废热,从离开 SCR 的处理过的气体中回收能量。在此应用中,加热元件以 0.6-1 rpm 的速度旋转,将热量传递给未处理的气体进料,从而降低达到反应温度所需的额外加热水平。

目标: 通过减少达到 NOX (≈ 250 - 330oC) 破坏反应温度所需的额外加热来提高 NOX 排放系统的效率。

典型应用场景

随着工业向碳捕获与封存 (CCS) 迈进,回转式换热器技术也被整合进新方案中。

燃烧后碳捕获 (PCC) 工厂可以作为新发电厂的一部分进行开发或改造。它们捕获烟气中的二氧化碳 (CO2),用作产品或储存在永久性地下地质储存设施中。

该工艺的换热器类似于烟气换热器 (GGH),其温度与 FGD 工艺相似。该换热器的作用是在烟气脱硫装置之前冷却烟气,并在碳捕获装置之后重新加热处理过的气体,以便排放到烟囱。

目标: 降低捕获装置前未处理气体的温度,并利用该温度重新加热处理过的气体,以降低羽流可见度并具有足够的浮力以离开烟囱。

适用产品

众多工业过程需高温加热,能耗极大。这些过程消耗大量能源,因此任何减少需求的方法都可以节省大量运营成本。

Howden Rothemühle 品牌推出的 DREBS 换热器为此提供了解决方案。这是一种旋转再生器燃烧器系统,利用陶瓷表面从高温废气中吸热,再通过旋转将热量传递给空气流。

与传统热回收器相比,DREBS 可应用于更高温度(高达 1200oC)。由于热效率高达 >85%,与传统换热器相比,节能效果可翻倍。

目标: 与传统换热器相比,燃烧器和干燥器的效率可提高高达 100%。

典型应用

Howden 自 1923 年首次与发明人 Fredrik Ljungström 成立合资企业以来一直参与回转式再生换热器的开发。我们自己的产品技术一直在通过不断的研究、开发和分析进行设计改进,以优化产品性能和可靠性。

Rothemühle 品牌于 2021 年加入,拥有近 90 年的换热器经验。

我们的能力从确保我们庞大的全球换热器基础继续为客户提供服务,再到根据新兴的工业需求调整技术。

这些换热器设计用于连续运行,仅需极少维护。为确保回转式热交换器始终保持最佳性能,我们配备全球工程师团队,为旗下 Howden、Sirocco、Tallares Sanchez Luengo(TSL)、Rothemühle(含 LUGAT)自有品牌产品提供专业维护服务。

由于工厂工况随着时间的推移而变化,我们也提供评估、实施性能改进和寿命延长等一系列工程服务。

Howden 换热器可根据不同工艺和工程配置的需求,灵活应对各种气体流量、温度和场地条件,为客户量身定制解决方案。

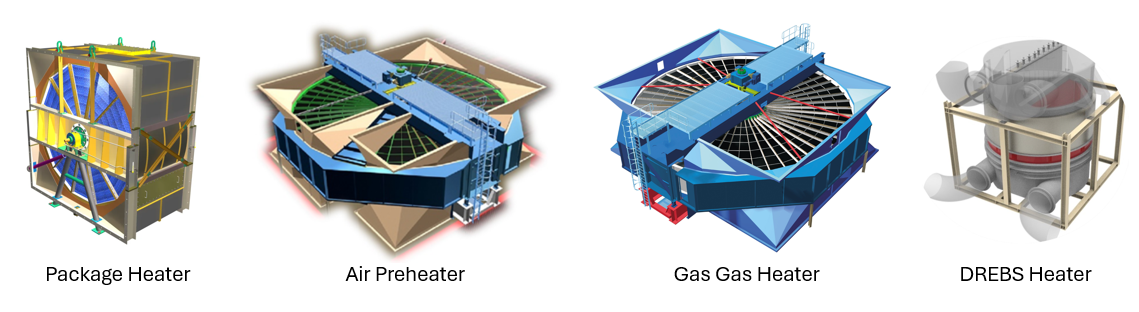

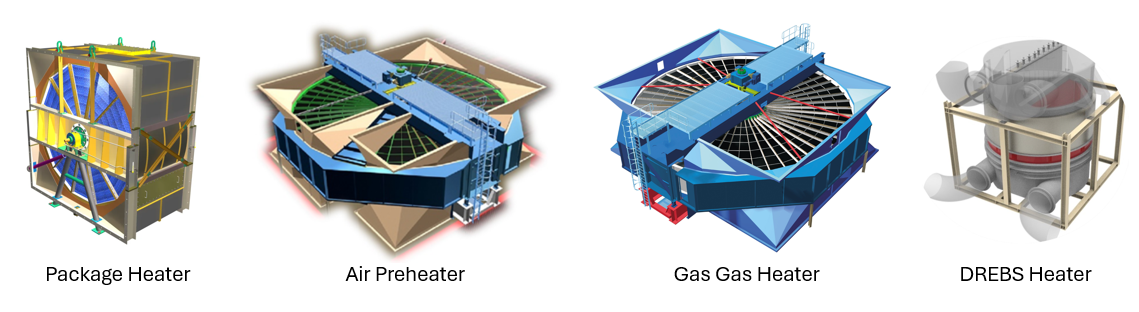

| 产品 | 热能回收 | 气体体积 | 气体温度 | 足迹 | 泄漏 | 应用 |

|---|---|---|---|---|---|---|

| 封装换热器 | 高达 15MW | 45 至 200 吨/小时 | 高达 370o C (698o F) | 大约3.5 m2至 5.4 m2 | <5% 使用单/双径向和双轴向密封 | 小规模空气预热 |

| 空气预热器 | 高达 100MW | 200 至 3600 吨/小时 | 高达 500o C (932o F) | 高达 625m2 | <5% 采用迷宫式多重密封,配有可选扇形板 | 大容量空气预热 |

| 烟气再热器 | 高达 100MW | 200 至 3600 吨/小时 | 高达 500o C (932o F) | 高达 625m2 | <0.5% 使用迷宫式多重密封、吹扫和清除系统以及可选扇形板 | 用于 FGD 的气体再热和用于 SCR 的气体预热 |

| DREBS 换热器 | 高达 7MW | 高达 40 吨/小时 | 高达 1200o C (2192o F) | 高达 16m2 | 根据压力和应用场景的不同而有所变化 | 用于金属、玻璃以及烤炉应用的高温能量回收 |

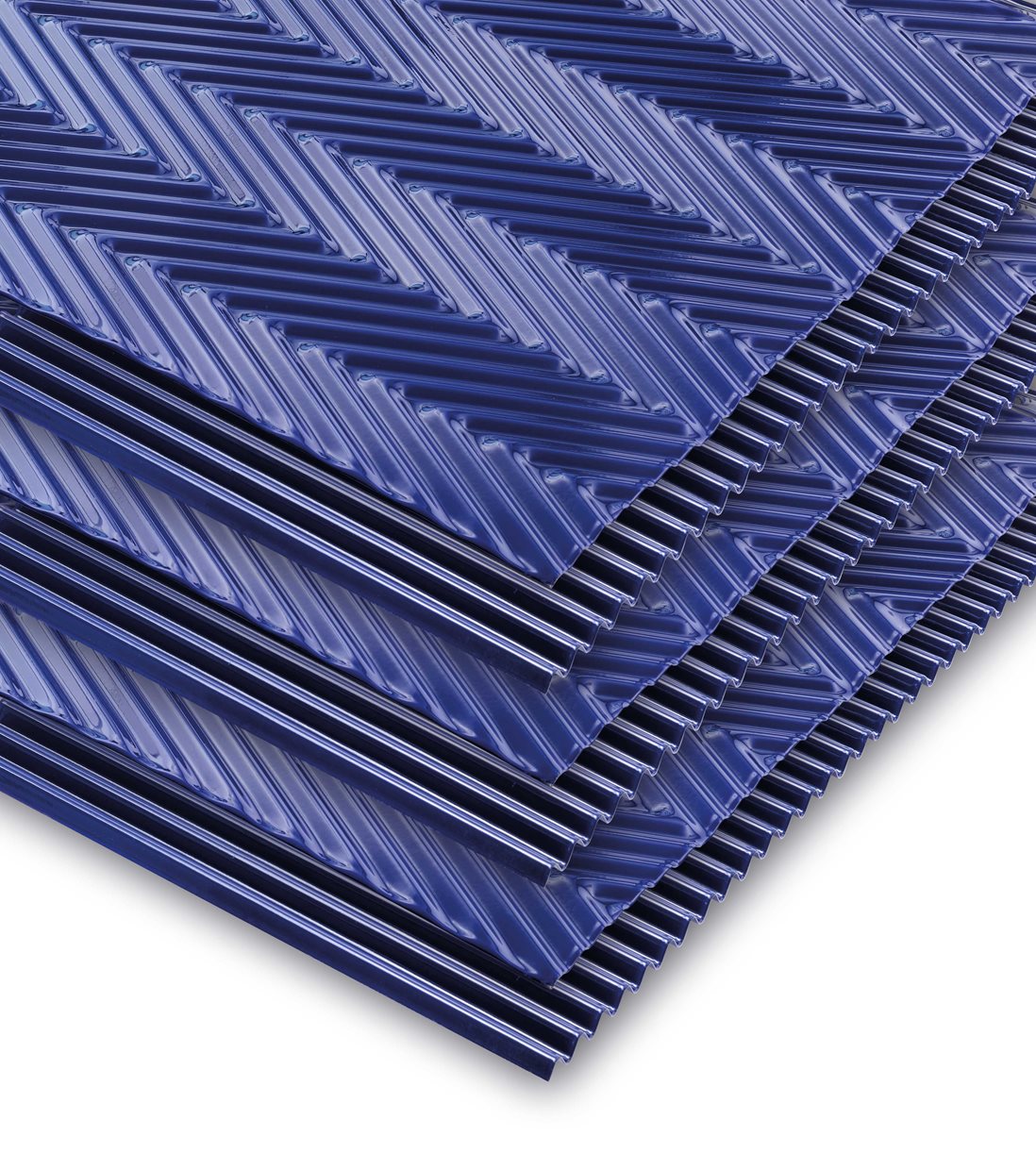

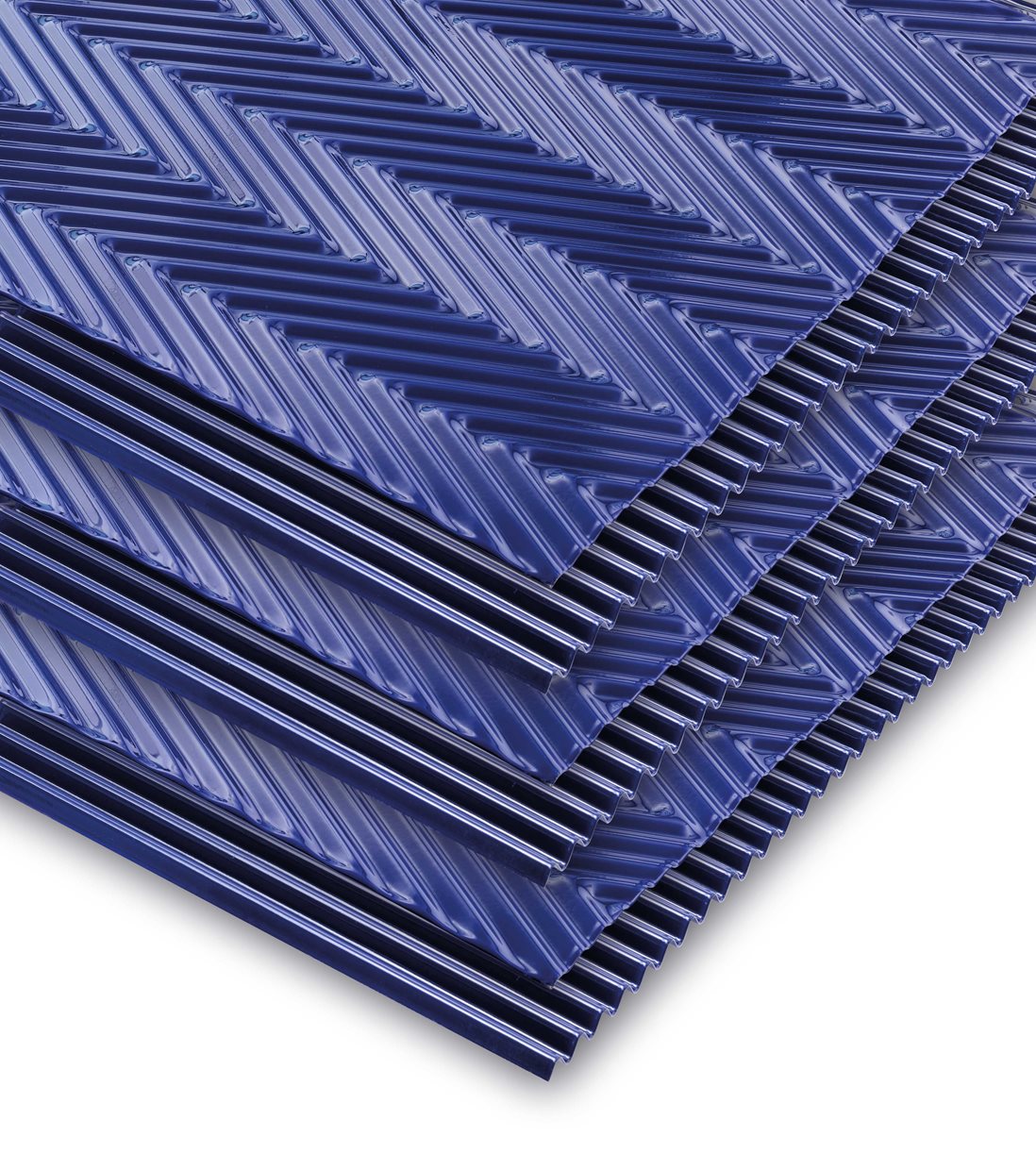

要维持最高效率,需深入了解换热器在不同燃料条件下的长期运行表现。换热元件是根据具体应用场景和燃料类型专门设计的。

我们拥有种类繁多的波形,能够针对任何情况实现热力学性能、压降和清洁便利性之间的平衡。这些波形可以从我们的产品系列中选择(包括世界首款上市销售的双波形元件),我们也可以对您已有的波形进行匹配。

我们在在生产搪瓷元件领域处于全球领先水平。在苛刻的环境中使用时,这些元件既具有防腐蚀性能,又非常便于清洁。

元件在换热器性能中起着关键作用,但我们通过系统化地研究污染与清洗周期的科学,开发出一整套综合系统,其整体效果远超各部分的简单叠加:

包括 SureCoat™(高性能珐琅涂层)、SurePack™(优化的元件装配结构)以及 Enerjet™(先进清洗系统)。

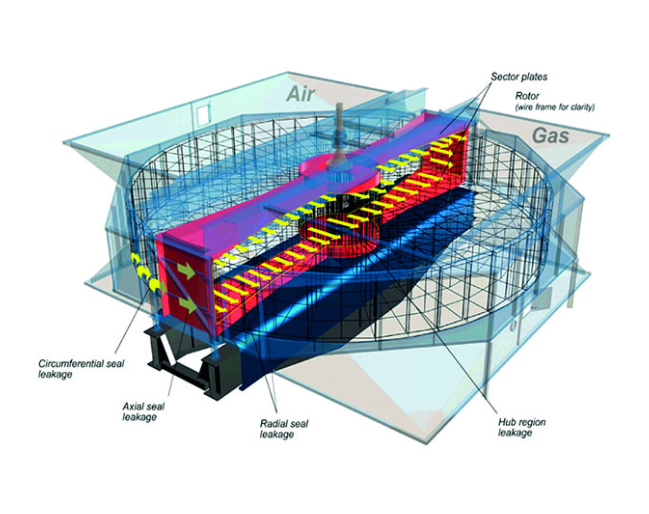

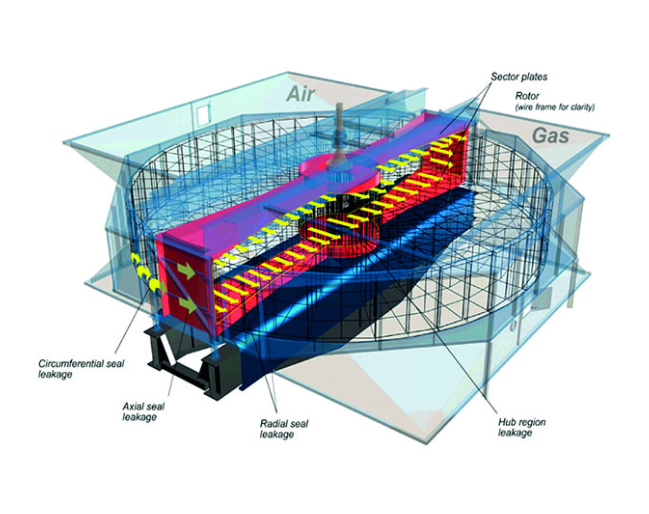

最大限度减少气体泄漏是一个关键考量,Howden 为此开发了一系列创新方案。

VN 密封系统能在较长时间内保持持续低泄漏率。在 GGH(气气加热器)中,还采用了其他方法,例如用洁净气体加压密封空间,或使用吹扫风扇制造微小压差。清扫系统随后利用已处理气体将元件中的脏气体排出。

接触式密封件旋转式热交换器的柔性接触式密封件是一种减小转子热端与分隔空气和气体流动的扇形板之间直接泄漏间隙的方法。

标准密封件因不断弯曲而容易失效,因此 豪顿进行了大量的开发计划,以优化适合应用的接触式密封件,从而大幅降低了泄漏情况。由于密封件在间隙小且均匀的情况下效果最佳,因此可以结合抛物线扇形板一起使用来进一步减少泄漏情况。

抛物线扇形板环境审查力度的提高以及对最高效率水平需求的增加,共同推动了 豪顿开发出抛物线扇形板(正在申请专利),并将其用于我们的换热器之中。

热端扇形板设计成具有可变刚度,当驱动时会呈抛物线状变形,以适应变形操作转子的形状。这样可以最大限度地减少热端泄漏间隙。

豪顿抛物面扇形板不仅可以降低工厂的引风机功率,还可以减少流向下游减排设备的气体质量。

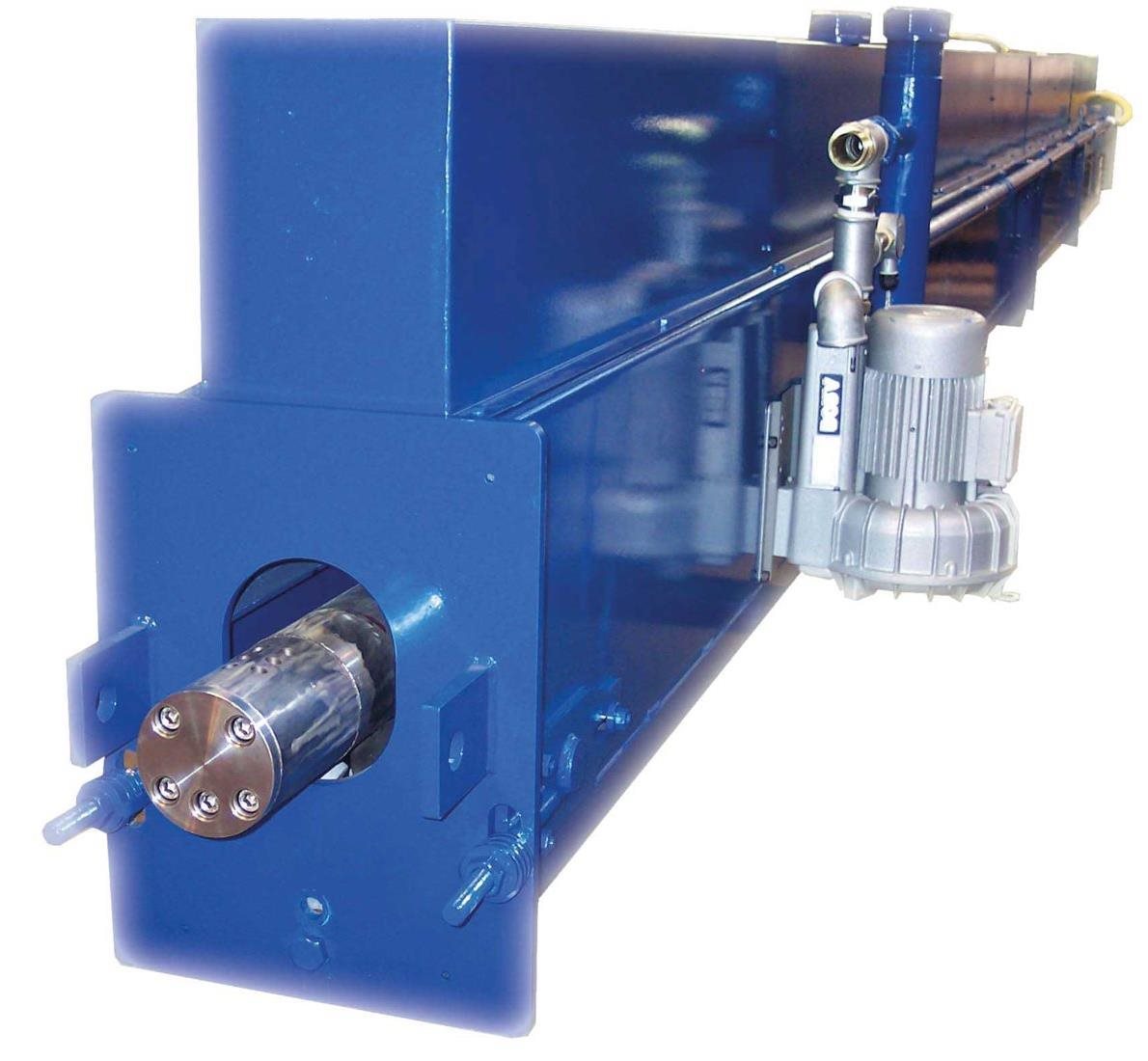

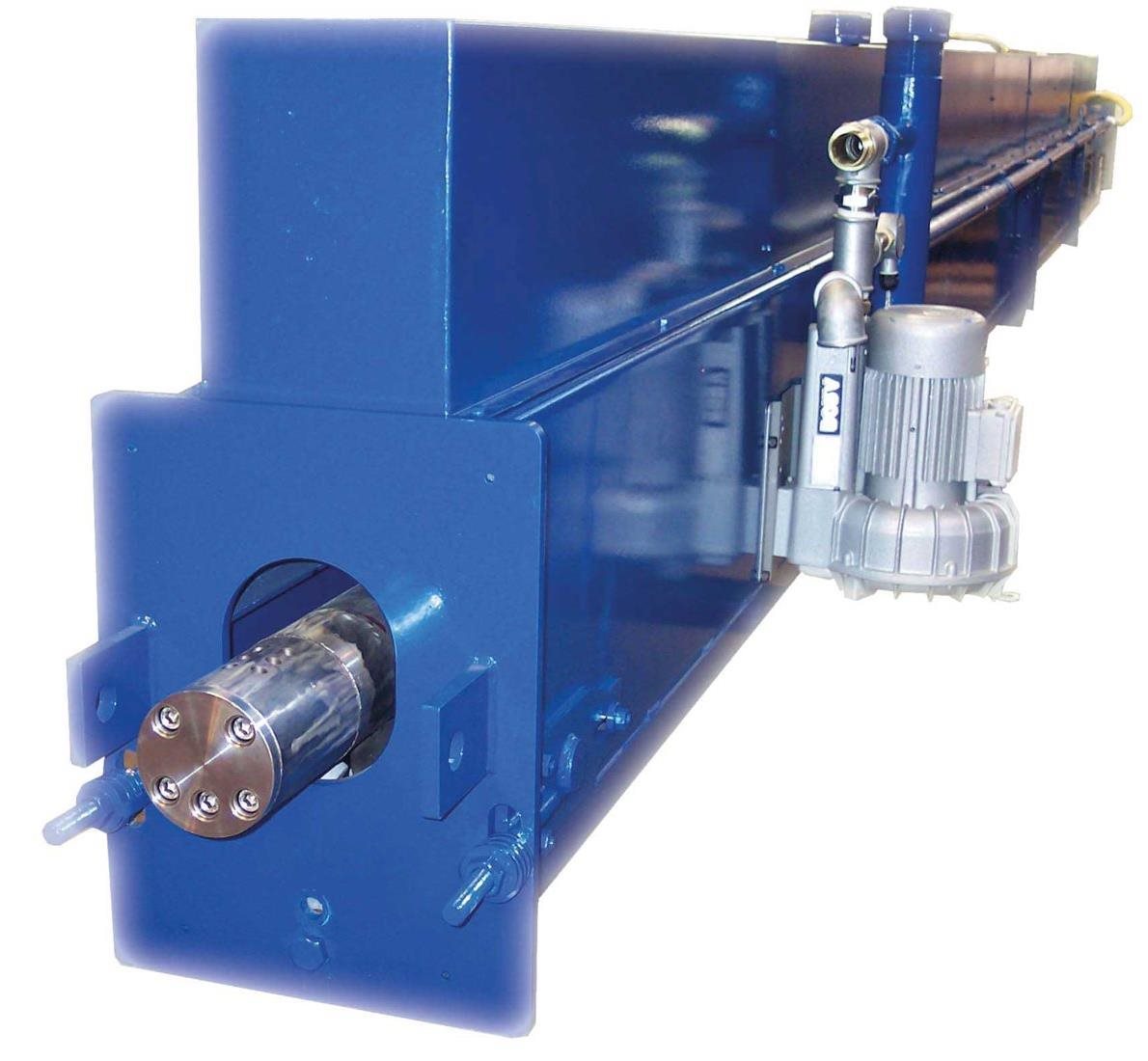

与管式或板式回热式热交换器不同,结垢不会引发回转式再生热交换器的传热性能下降。结垢会增加压差,从而提升风机功耗并加剧泄漏。但保持元件清洁可提高设备可用性,且只需按计划维护,减少额外维护需求。

豪顿Enerjet™ 清洁系统是一种使用在线高压水冲洗空气预热器的方法,旨在在空气预热器正常使用时对严重结垢的换热元件进行有效且高效的清洁。

Enerjet™ 系统可与任何制造商的任何类型的空气预热器配合使用,并且可与大多数类型的元件配合使用。

Enerjet™ 与 SureCoat™(高性能珐琅元件)和 SurePack™(优化的元件包装)相结合,提供了一种系统化的污染与清洁周期管理方法,其整体效果远超各部分的简单叠加。

Howden 换热器可根据不同工艺和工程配置的需求,灵活应对各种气体流量、温度和场地条件,为客户量身定制解决方案。

| 产品 | 热能回收 | 气体体积 | 气体温度 | 足迹 | 泄漏 | 应用 |

|---|---|---|---|---|---|---|

| 封装换热器 | 高达 15MW | 45 至 200 吨/小时 | 高达 370o C (698o F) | 大约3.5 m2至 5.4 m2 | <5% 使用单/双径向和双轴向密封 | 小规模空气预热 |

| 空气预热器 | 高达 100MW | 200 至 3600 吨/小时 | 高达 500o C (932o F) | 高达 625m2 | <5% 采用迷宫式多重密封,配有可选扇形板 | 大容量空气预热 |

| 烟气再热器 | 高达 100MW | 200 至 3600 吨/小时 | 高达 500o C (932o F) | 高达 625m2 | <0.5% 使用迷宫式多重密封、吹扫和清除系统以及可选扇形板 | 用于 FGD 的气体再热和用于 SCR 的气体预热 |

| DREBS 换热器 | 高达 7MW | 高达 40 吨/小时 | 高达 1200o C (2192o F) | 高达 16m2 | 根据压力和应用场景的不同而有所变化 | 用于金属、玻璃以及烤炉应用的高温能量回收 |

要维持最高效率,需深入了解换热器在不同燃料条件下的长期运行表现。换热元件是根据具体应用场景和燃料类型专门设计的。

我们拥有种类繁多的波形,能够针对任何情况实现热力学性能、压降和清洁便利性之间的平衡。这些波形可以从我们的产品系列中选择(包括世界首款上市销售的双波形元件),我们也可以对您已有的波形进行匹配。

我们在在生产搪瓷元件领域处于全球领先水平。在苛刻的环境中使用时,这些元件既具有防腐蚀性能,又非常便于清洁。

元件在换热器性能中起着关键作用,但我们通过系统化地研究污染与清洗周期的科学,开发出一整套综合系统,其整体效果远超各部分的简单叠加:

包括 SureCoat™(高性能珐琅涂层)、SurePack™(优化的元件装配结构)以及 Enerjet™(先进清洗系统)。

最大限度减少气体泄漏是一个关键考量,Howden 为此开发了一系列创新方案。

VN 密封系统能在较长时间内保持持续低泄漏率。在 GGH(气气加热器)中,还采用了其他方法,例如用洁净气体加压密封空间,或使用吹扫风扇制造微小压差。清扫系统随后利用已处理气体将元件中的脏气体排出。

接触式密封件旋转式热交换器的柔性接触式密封件是一种减小转子热端与分隔空气和气体流动的扇形板之间直接泄漏间隙的方法。

标准密封件因不断弯曲而容易失效,因此 豪顿进行了大量的开发计划,以优化适合应用的接触式密封件,从而大幅降低了泄漏情况。由于密封件在间隙小且均匀的情况下效果最佳,因此可以结合抛物线扇形板一起使用来进一步减少泄漏情况。

抛物线扇形板环境审查力度的提高以及对最高效率水平需求的增加,共同推动了 豪顿开发出抛物线扇形板(正在申请专利),并将其用于我们的换热器之中。

热端扇形板设计成具有可变刚度,当驱动时会呈抛物线状变形,以适应变形操作转子的形状。这样可以最大限度地减少热端泄漏间隙。

豪顿抛物面扇形板不仅可以降低工厂的引风机功率,还可以减少流向下游减排设备的气体质量。

与管式或板式回热式热交换器不同,结垢不会引发回转式再生热交换器的传热性能下降。结垢会增加压差,从而提升风机功耗并加剧泄漏。但保持元件清洁可提高设备可用性,且只需按计划维护,减少额外维护需求。

豪顿Enerjet™ 清洁系统是一种使用在线高压水冲洗空气预热器的方法,旨在在空气预热器正常使用时对严重结垢的换热元件进行有效且高效的清洁。

Enerjet™ 系统可与任何制造商的任何类型的空气预热器配合使用,并且可与大多数类型的元件配合使用。

Enerjet™ 与 SureCoat™(高性能珐琅元件)和 SurePack™(优化的元件包装)相结合,提供了一种系统化的污染与清洁周期管理方法,其整体效果远超各部分的简单叠加。

总部 +44 141 885 7500

封装加热器 +34 968 32 00 64