文章

详细了解我们的产品和服务每天为像您一样的客户提供哪些帮助。

如今,科学家常使用“气候变化”一词来描述复杂的变化,气候变化受温室气体浓度影响,现在,后者正在影响我们地球的天气和气候系统。The main cause of global greenhouse gas emissions is the release of carbon (CO2) emissions from burning fossil fuels. For that reason, governments, industries and technology companies are working together to decarbonise multiple industries and accelerate the global energy transition - the global energy sector’s dependence, production and consumption from fossil-based systems of energy to renewable energy sources like wind and solar.

Sitting at the number-one spot on the periodic table, Hydrogen offers an alternative energy source with several benefits. It contains more energy per unit of weight than fossil fuels and in particular, it can be used directly as a fuel, as energy storage, to generate electricity, or even as a chemical feedstock. 1 kg of hydrogen (kgH2) contains 33.33 kilowatt hour (kWh) of usable energy, whereas petrol and diesel only hold about 12 kWh/kg. It can be used in a variety of applications and does not generate any CO2 emissions when it burns, it produces only water. As a viable energy source with scalable solutions, hydrogen is a powerful enabler and a vital component of achieving net-zero emissions economies however, it will require investment and a large scaling up of its production and use to reduce costs to make it viable.

If the energy system is to rely on hydrogen fuels for decarbonisation, we need first understand where hydrogen coming from and why this element has been favoured as a tool to transition. Hydrogen is the lightest and most abundant known chemical element. The Hydrogen molecule - at standard temperature and pressure - is an odourless, colourless, tasteless, non-toxic, highly combustible gas, with the highest specific energy content of all conventional fuels.

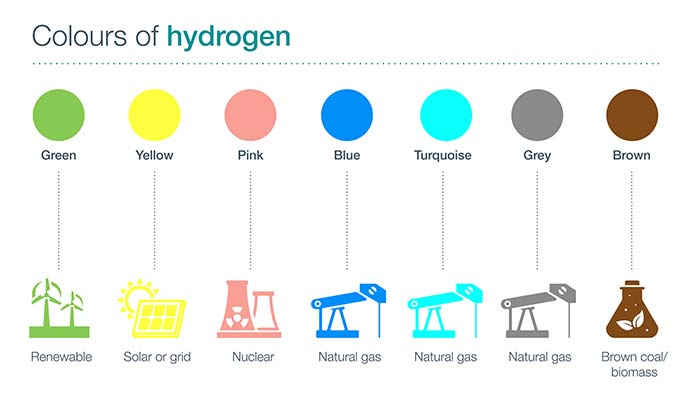

Hydrogen can be produced via different methods, and each one produces different amounts of carbon dioxide as a by-product. Depending on the production methods and emissions produced, hydrogen can be green, yellow, pink, blue (reforming with CCUS), turquoise (Methane pyrolysis), grey (reforming without CCUS) or brown.

Hydrogen can also be produced biologically through the action of living organisms, a type of biofuel, biohydrogen. On its own this is CO2 neutral but can be combined with carbon capture, utilisation and storage (CCUS) to be CO2 negative.

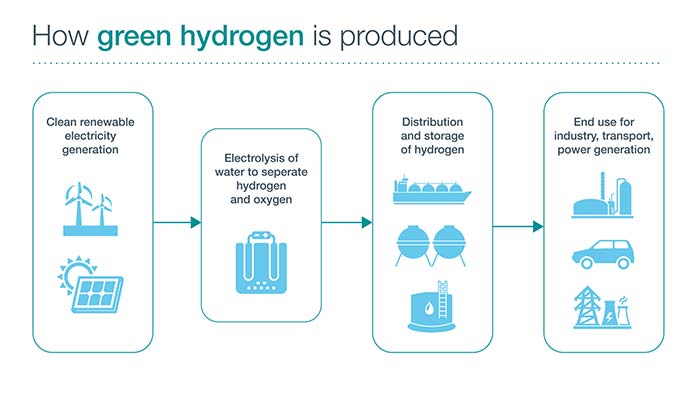

To be classed as ‘green energy’ only electricity from renewable energies is used to generate the hydrogen – green hydrogen - so no CO2 emissions are produced, making the process climate neutral. Green hydrogen is the only 100% sustainable and commercially viable hydrogen. According to the European Commission, 96% of hydrogen production is produced through grey hydrogen, emitting significant amounts of CO2 emissions in the process. Because of the end impact, the source is important element where renewable sources need to be utilised to meet climate neutrality objectives and decarbonise sectors.

Green hydrogen is produced from renewable energies – such as wind, hydro or solar farms. The energy from these renewables sources are used to power electrolysers to produce hydrogen through the electrolysis of water – this is a process of using electricity to split water into the two individual elements: hydrogen and oxygen.

Although blue hydrogen is a necessary step in the transition until green hydrogen can scale up, only hydrogen produced from renewable sources can truly accelerate the energy transition and meet Paris Agreement climate targets, as neither its production process nor usage encounter any generation of CO2 emissions.

Using the renewable energies directly can be challenging in terms of availability. For example, even when they are abundant, they are not always available in places where they are needed. And, in other cases, renewable energy is generated in excess, but cannot all be used.

But with hydrogen as an energy storage, it is now possible to balance the two gaps in the market between supply and demand. It is now possible to produce green hydrogen in areas where or when renewable energies are available, allowing hydrogen to serve as the storage solution and to be transported to other areas where or when it is needed.

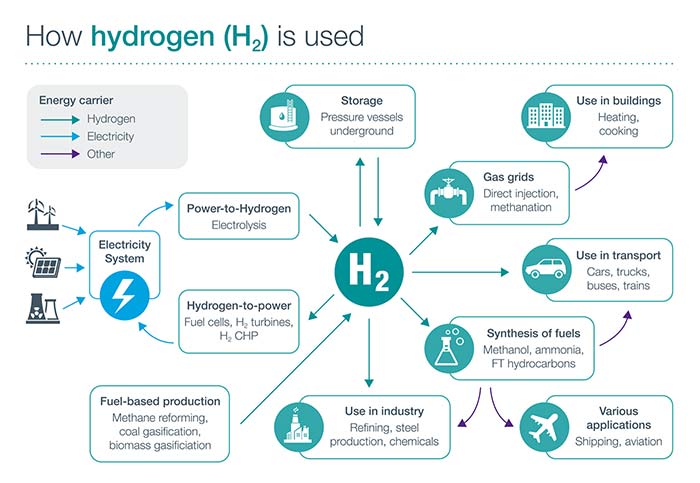

Hydrogen offers several benefits that increase its potential to replace fossil fuels and decarbonise industries that heavily depend on the fuel source. In particular, hydrogen can be used directly as a fuel, as energy storage, or to generate electricity (via fuel cells). It can be used in a variety of applications, as demonstrated in the following diagram:

Hydrogen is stored in pressure vessels or underground (including salt caverns). Hydrogen gas has the highest energy per mass of any fuel, this makes it important to develop advanced storage methods that have potential for higher energy density.

Other challenges for storage in tanks come from the compatibility of materials with high pressure hydrogen, which due to its specific properties can cause various types of metal failures. Exploring metal compatibility with high pressure pure hydrogen is still a research field.

To make hydrogen usable, the process requires one or more compressors to increase the pressure of hydrogen by reducing its volume – compressed hydrogen. Hydrogen compression is a key aspect in hydrogen applications and applied across the value chain from production to end use in refuelling stations. The compressor is the heart of the system.

Howden compression technologies can handle and optimise hydrogen across the value chain from production to storage, distribution, transmission and end use such as refuelling stations and Power-to-X applications.

There are different types of compressors that are able to compress hydrogen. The type of compressor selected depends on the application and pressure required. Below is an overview and more information can be found on the product pages:

A reciprocating (motion of back and forth) compressor is a machine that uses a cylinder with a piston to compress (hydrogen) gas to pressurize. During the compression process, the piston movement causes suction of the gas in the cylinder during one part of the compression cycle and increase the pressure by reducing the volume available for the gas during the other part of the compression cycle. Once the pressure inside the cylinder exceeds the outlet pipes’ pressure, valves open and allow gas to flow out.

Howden’s unique Free Floating Piston™ system uses a cushion of process gas to support the piston, eliminating rider ring wear and greatly extending intervals between maintenance, reducing downtime and cost.

Howden continues to be at the leading edge of reciprocating compressor innovations. Over the past decades, Howden’s innovative approach to reciprocating compressors has led to market-leading technology advancements.

Reciprocating compressors show two key advantages for hydrogen compression:

These are the reasons why these compressors are an essential component of our portfolio for hydrogen handling.

A diaphragm compressor is a variant of the reciprocating compressor. Also referred to as a membrane compressor as it uses a diaphragm or membrane to compress the gas while ensuring complete isolation from the lubricated parts of the compressor. The sealing of the compression stages is achieved by static parts only which makes this type of compressor specifically well suited to safely and efficiently handle gas at high pressure.

Henri Corblin invented the diaphragm compressor in the early 20th century. As part of Howden’s portfolio, it has remained the optimal solution for high pressure compression of gasses ever since.

Howden diaphragm compressors provide market-leading high-pressure compressor solutions. We carry considerable expertise in high-pressure applications, up to and exceeding 3000 bar discharge pressure.

The hybrid compressor brings together the benefits of our piston and diaphragm compressors in one single compressor. The compressor combines the piston compressors large volumes compression capabilities at lower pressures and utilising diaphragm capabilities to achieve very high discharge pressures. This technology is ideal to compress gas from atmospheric production pressures up to the required process or storage pressure.

As pioneer of screw compressor technology, the screw compressor revolutionised designs for refrigeration and gas handling plants worldwide. For hydrogen applications, the screw compressor is applicable to refrigerant pre cooling section of hydrogen liquefaction plants.

CO2 emissions contribute to climate change, which is already displaying serious consequences for humans and our environment. For that reason, there is a need to replace fossil fuels with a clean fuel such as hydrogen that does not generate any CO2 emissions when it burns. Hydrogen can support a clean, secure and affordable energy future and decarbonise a range of sectors. This will enable us to protect our environment and ensure it is healthy and liveable for the next generation.

Hydrogen has a huge part to play in decarbonisation – particularly in hard to abate sectors.

There is no doubt hydrogen will and is playing a vital role in achieving decarbonisation of the energy system. However there are challenges that need to be addressed.

Howden is recognised as a global leader of hydrogen compression solutions. With over 100 years of experience in compression of hydrogen, we have developed highly innovative solutions for our customers.

Find out more about our Hydrogen offering here: