Chart Industries and Flowserve announce a merger of equals to create a differentiated leader in industrial process technologies. Learn More.

×

空气冷却热交换器

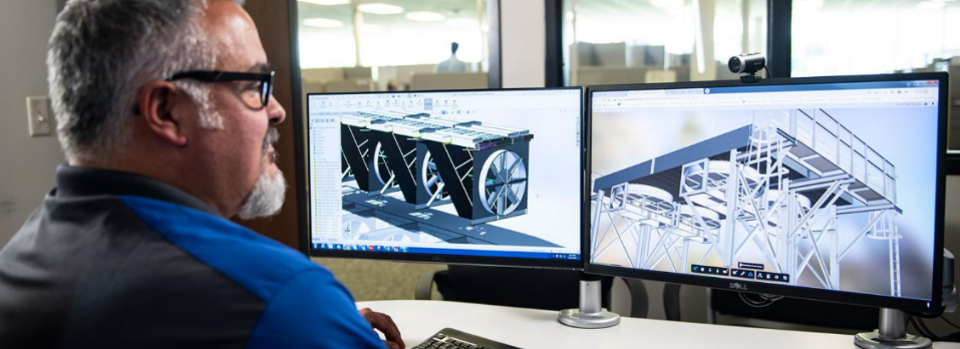

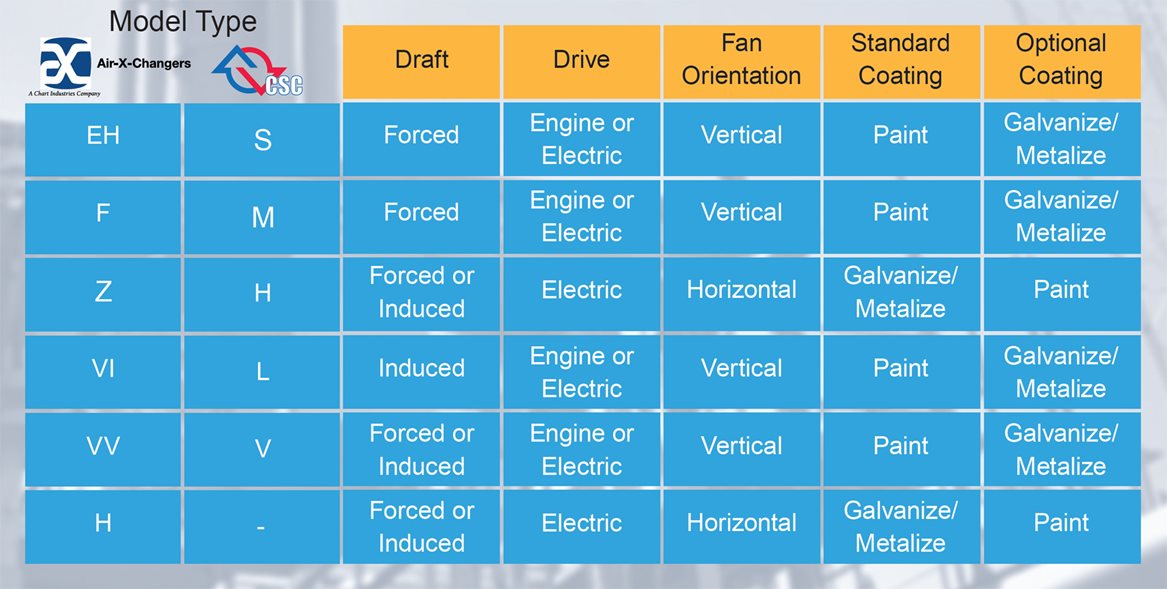

通过 Hudson Products、Air-X-Changers、Smithco、Hammco 和 Cooler Service Company 等品牌,Chart 汇集了为上游、中游、下游、精炼厂、石化、电力和其他领域提供传热解决方案的值得信赖的领导者。

-1134x670.jpg)

.jpg?ext=.jpg)

请求报价

请求报价

通过电子邮件发送查询

通过电子邮件发送查询

查看我们的办公地址

查看我们的办公地址

加入我们的团队

加入我们的团队